22

2025

-

09

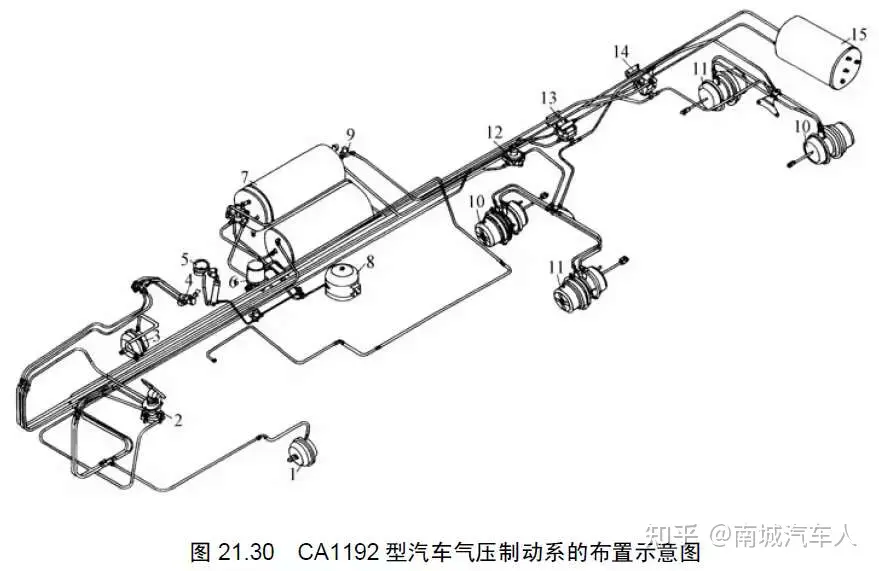

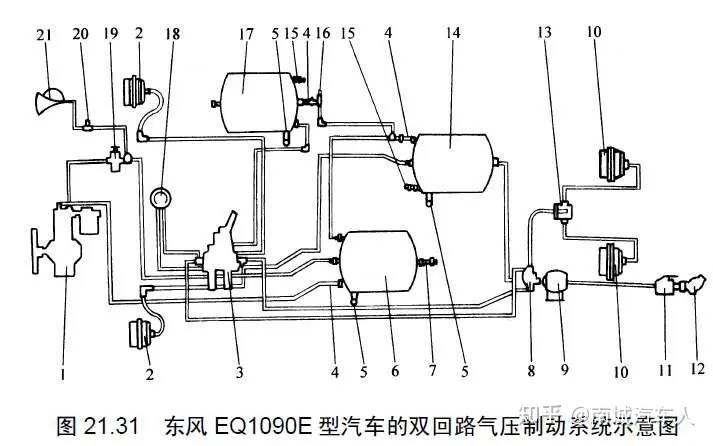

Introduction to the vehicle air pressure braking system and air circuit principles

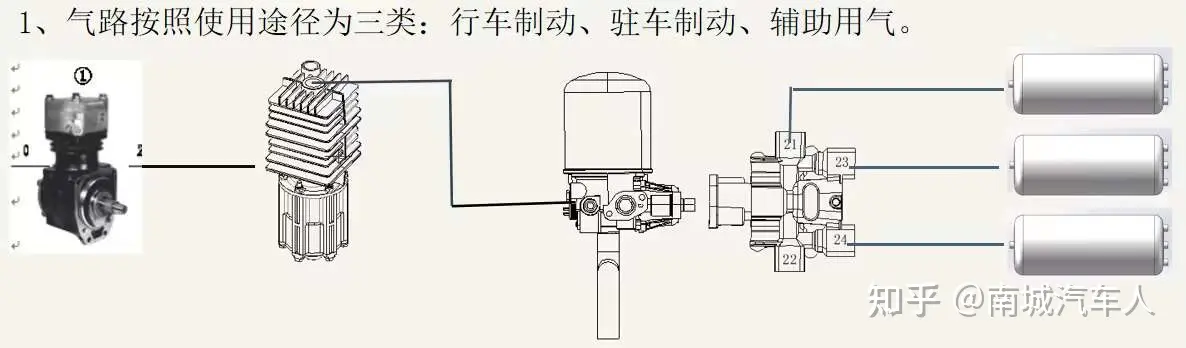

1. The air system is divided into three categories based on usage: driving brake, parking brake, and auxiliary air use. The air compressor draws in air, compresses it, and after pressurizing, delivers the final high-temperature gas through a spiral steel pipe to the condenser. As it passes through the condenser, the spiral structure inside causes water, oil, and other contaminants to be thrown against the inner wall of the valve body. The contaminants flow along the inner wall towards the outlet, while simultaneously reducing the temperature of the compressed air. The gas coming out of the condenser reaches the dryer, and after filtering and drying through the dryer, the outgoing gas passes through the four-way protection valve and is divided into three routes, entering three sets of air storage tanks.

2. Vehicle braking: commonly known as foot brake.Controlled by the foot brake valve. When a foot presses the brake pedal, the force is transmitted to the foot brake valve, which opens the air circuit. The compressed air from the storage tank passes through the foot brake valve to the control port of the relay valve at port 4. The air enters the relay valve at port 4, pushing the piston to move, which opens the intake port 1 of the relay valve. The air from the storage tank enters the exhaust port of the relay valve (port 2), reaching the brake air chamber, pushing the piston in the brake air chamber to move, thus pushing the push rod to move, driving the adjustment arm to move, transmitting the force to the brake lever, pushing the brake shoes outwards to create friction between the friction pads and the brake drum, thereby achieving braking.

3. Parking brake: Also known as air brake, hand brake, or hand brake valve. In normal driving conditions, the air circuit remains open, and the intake port of the relay valve is in an open state. The gas from the air reservoir enters the brake air chamber through the intake port of the relay valve, pushing the diaphragm of the brake air chamber to compress the spring, which causes the spring to be compressed without braking action. When a parking brake is needed, the hand brake valve is opened, and gas flows through the hand brake valve to the terminal 4 of the relay valve, causing the diaphragm inside the relay valve to move, closing the intake port of the relay valve. The gas in the brake air chamber is released through the exhaust port of the relay valve, and the compressed spring rebounds due to the lack of force, driving the push rod to move. This, in turn, causes the adjustment arm at the bottom of the push rod to move, transmitting force to the brake rod, which pushes the brake shoes outward, creating friction between the friction pads and the brake drum, thereby achieving braking.

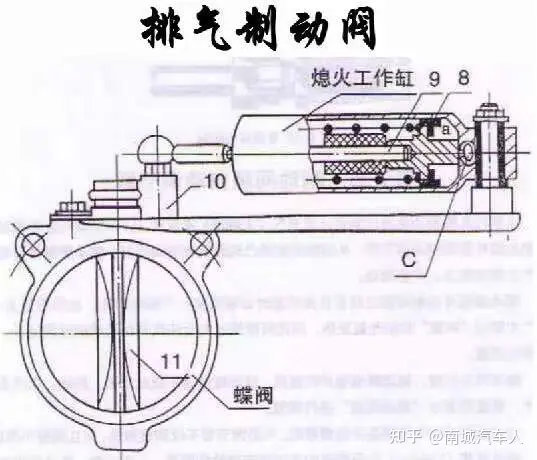

4. Exhaust braking.The driver presses the exhaust brake switch, and the solenoid valve controls the exhaust brake air circuit, causing the butterfly valve in the exhaust pipe to rotate, blocking the exhaust pipe. Compressed air enters the shut-off cylinder simultaneously when the button valve is opened. The piston in the shut-off cylinder moves under the action of the compressed air, and the push rod drives the governor handle through a linkage mechanism, stopping the fuel supply and preventing the engine from running, thereby achieving the braking effect.

5. Auxiliary gases: solenoid valve, air horn, lift system, clutch booster.

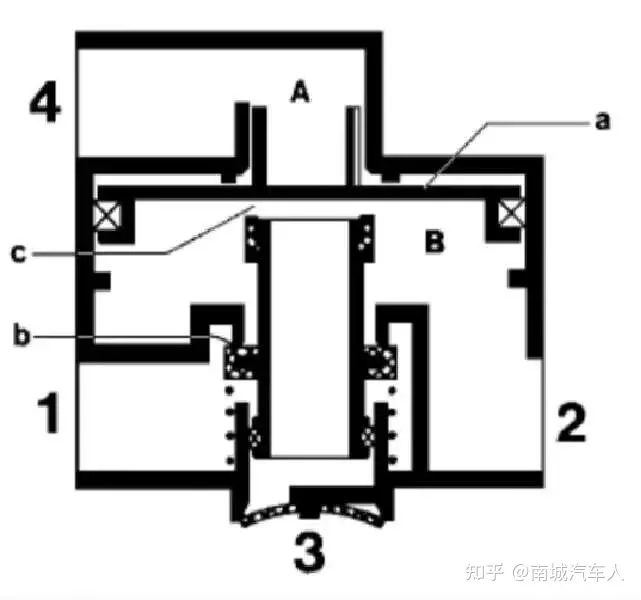

II. Introduction to the Principles of Various Components in the Air Circuit1. Basic Connections of the Air Circuit1 - Air Inlet2 - Air Outlet3 - Exhaust Port4 - Control Port

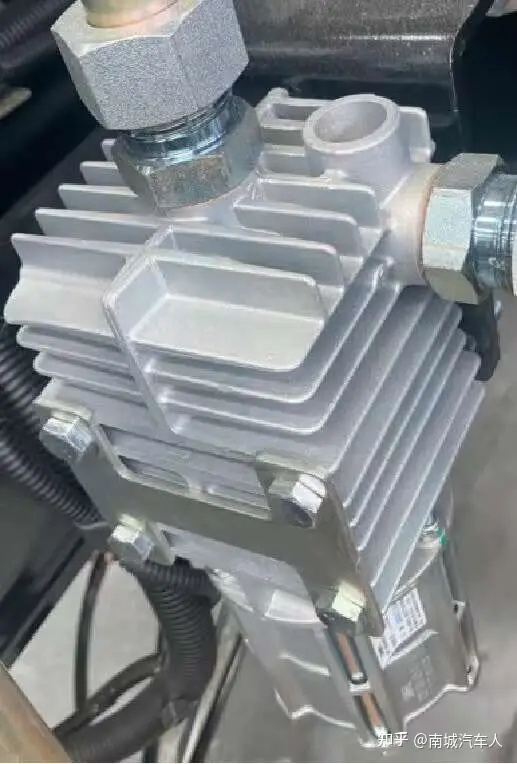

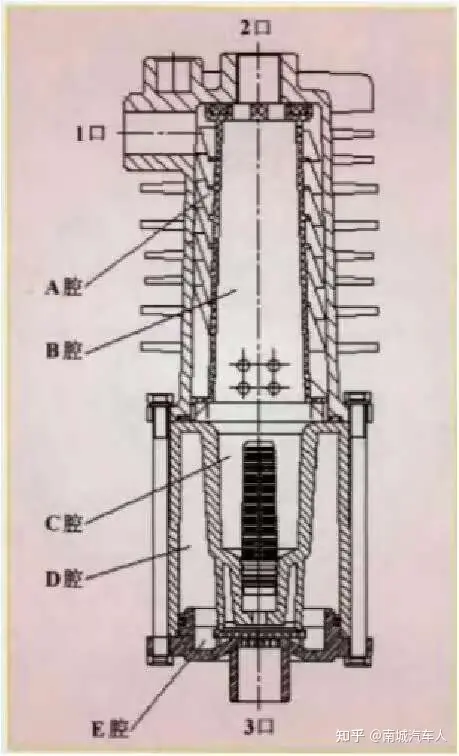

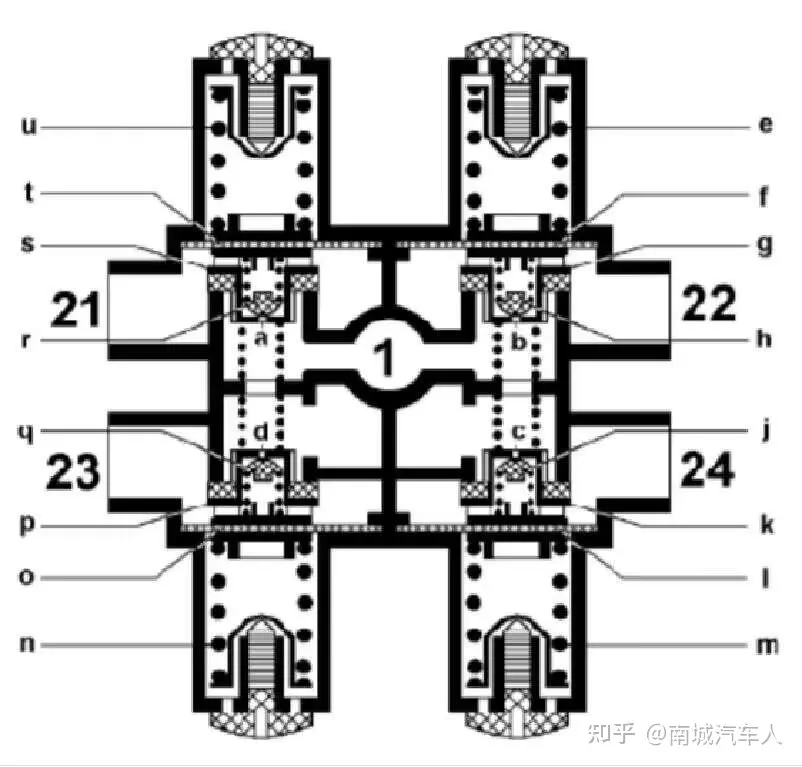

For example:11——First inlet12——Second inlet21——First outlet22——Second outlet2. Condenser1——Inlet2——Outlet3——Exhaust and waste discharge outletInstalled between the air compressor and the dryer, it separates oil and water droplets from the flowing compressed air during the air compression process. The condensed substances are collected by a filter screen, which gathers the corresponding oil and separates it from the compressed air. Water and oil stored in the chamber are discharged from the exhaust outlet 3. Cooling is done through the heat sink on the valve body, and the centrifugal force through the spiral channel separates water and oil from the compressed air. The structure is as shown in the right diagram; the compressed air coming from the compressor enters chamber A through inlet 1, flows into the spiral channel, where centrifugal force acts to fling pollutants such as water and oil onto the inner wall of the valve body, while also lowering the temperature of the compressed air. The pollutants flow along the inner wall, enter chamber C through small holes, and pass through a filter rod and diaphragm into chamber E. The compressed air, after removing water and oil, enters chamber B and is outputted from the outlet. When the dryer is unloaded, the pressure in chamber B drops, causing a pressure difference between chambers B and D, lifting the diaphragm. The water and oil stored in chamber E are discharged from the exhaust outlet 3.

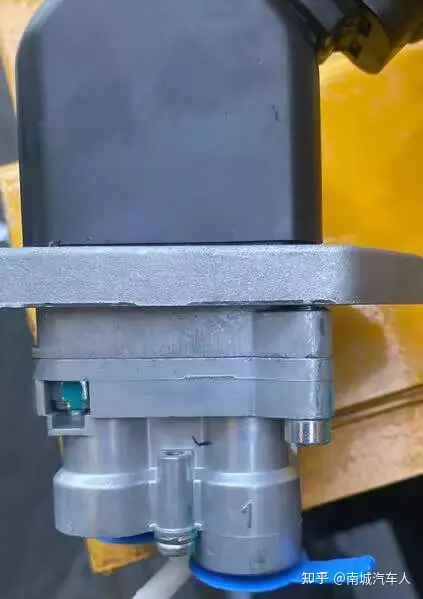

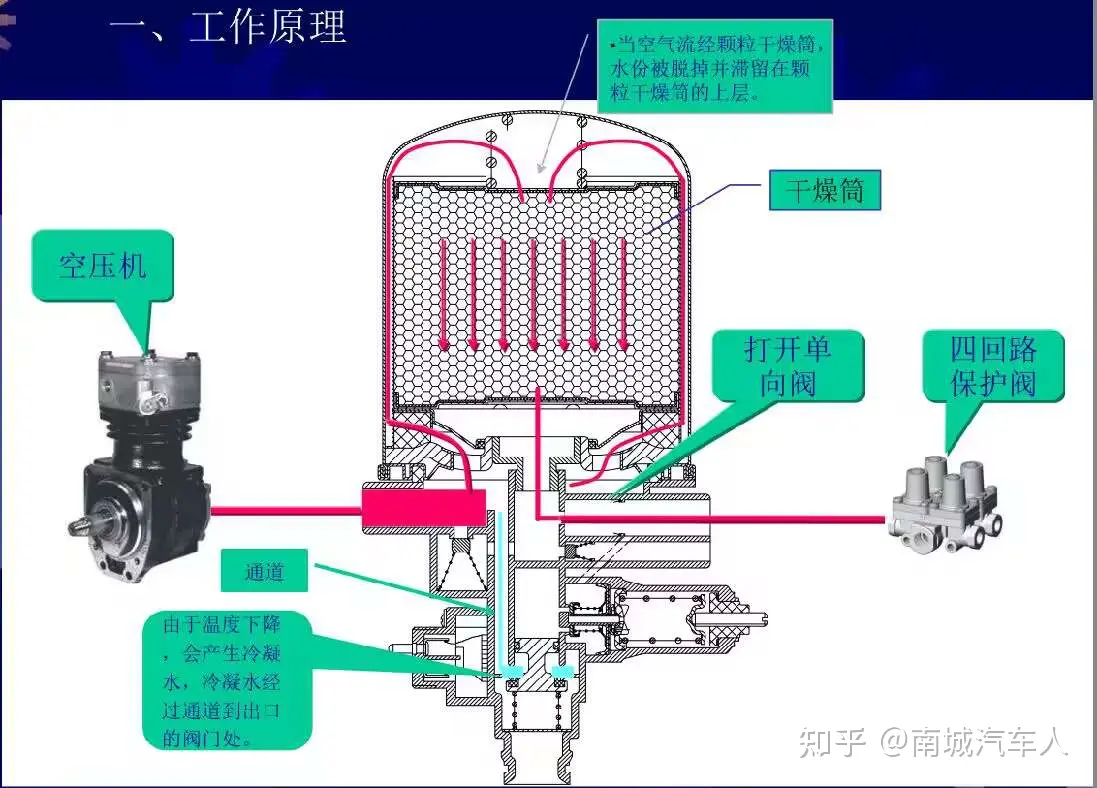

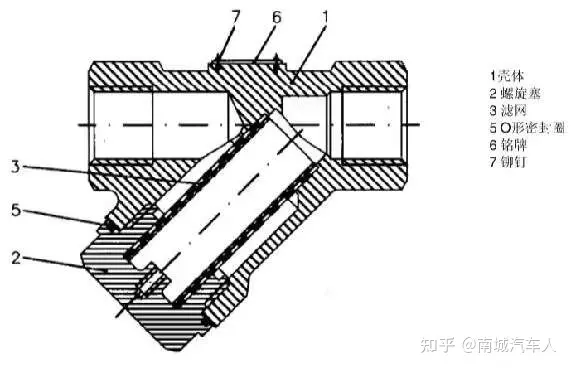

2. Condenser and Dryer1 - Inlet 2 - OutletThe air dryer mainly dries the compressed air coming from the air compressor. When the temperature is below 5 degrees Celsius, the heating rod starts to work to heat the moisture in the air. The drying cylinder is the key component of the air dryer, continuously regenerating the drying agent molecular sieve to maintain uninterrupted drying action. The sintered copper beads in the drying cylinder can filter out tiny particles and dust, and the molecular sieve can dry the compressed air to 0.03g/m^3.

Main functions of the dryer:1. Filter impurities from the gas.2. Absorb moisture from the gas.3. Regulate pressure in the braking system.4. Heat to prevent freezing in low-temperature environments.5. Pressure overload protection (1.3 MPA).

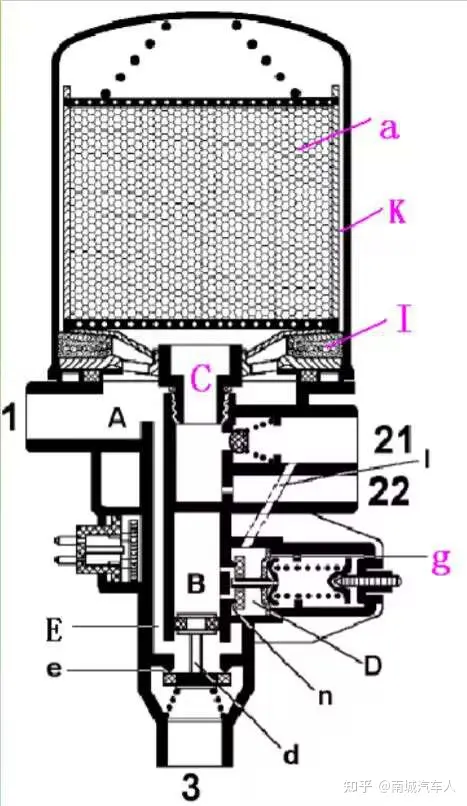

Compressed air enters chamber A through port 1, passes through dry filter mesh I and annular passage K to reach the upper part of the dryer. When the air flow goes through the desiccant a, moisture is adsorbed and retained on the surface of the desiccant a. After the dry air flow goes through passage C, a portion flows through port 22 to the air compressor to perform a cleaning function. Another portion flows through a one-way valve to port 21, and at the same time, some compressed air enters chamber D through orifice 1, acting on the membrane assembly g. When the system air pressure exceeds the preloading pressure of the spring, g drives valve n to move to the right, opening valve n and allowing compressed air to enter chamber B, pushing piston d down, which opens exhaust valve e to unload the air compressor. While the air compressor is unloading, the air at port 22 flows out through passage C, desiccant a, annular passage K, dry filter mesh I, passage E, and exhaust valve e, thereby exhausting the moisture adsorbed by desiccant a through backflow air. When the pressure at port 21 drops to 60-130KPa, due to the decrease in pressure in chamber D, the membrane assembly g moves to the left, closing valve n, and the compressed air in chamber B is discharged through the small hole. Under the action of the spring, piston d rises and closes exhaust valve e, allowing the air compressor to resume supplying air to the system, and the entire drying process restarts. The heater m can prevent components such as valve e from freezing, thus avoiding operational failures.

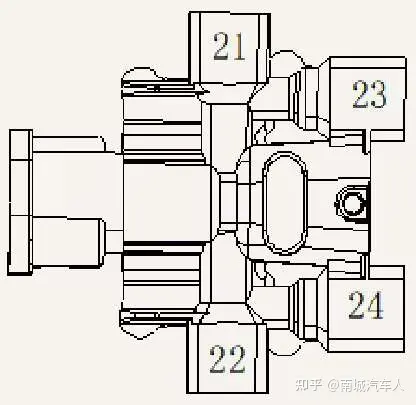

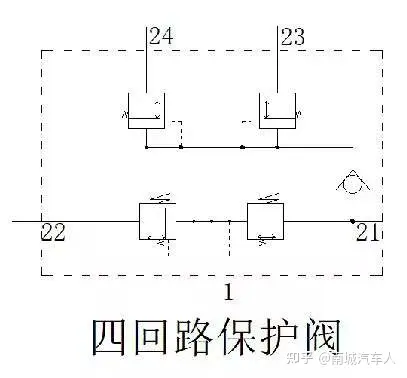

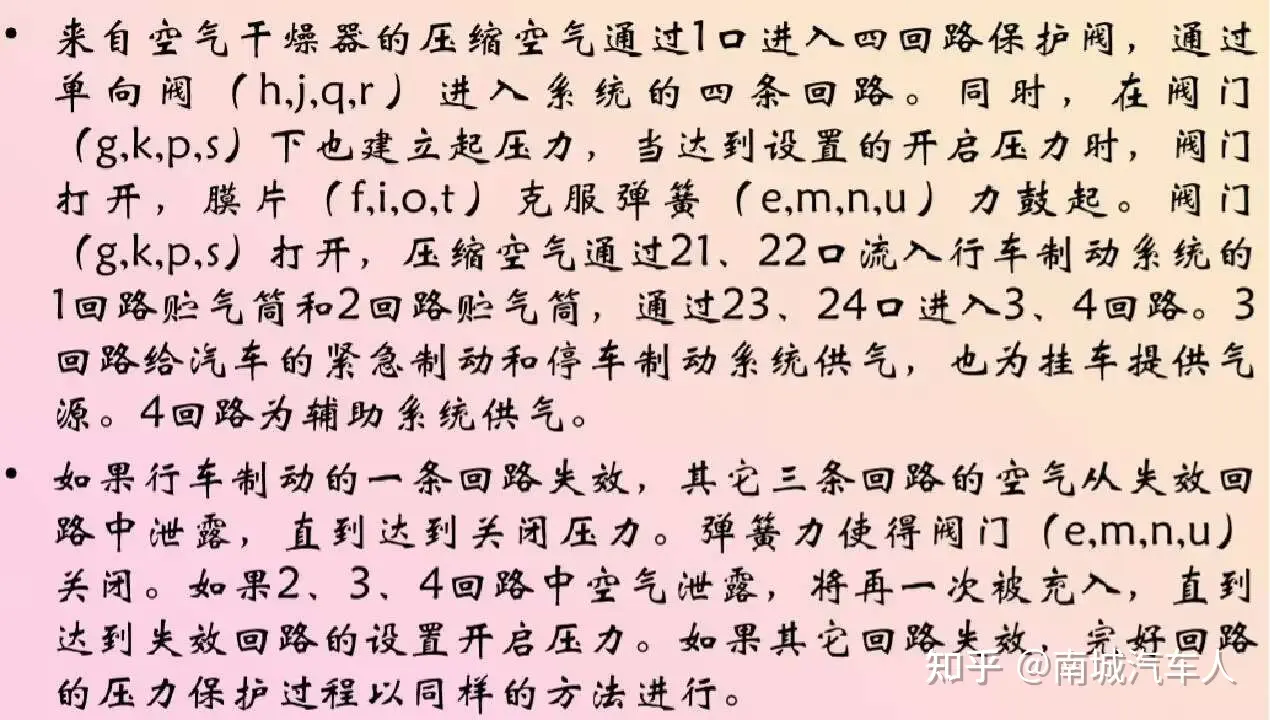

3. Four Circuit Protection ValveUnder normal conditions, the four circuit protection valve functions like a five-way valve. When one circuit fails, for example, if the first circuit fails, the pressure at outlet 21 continuously decreases due to leakage. Since all four valves are open at this point, gas from the other three circuits continuously replenishes the first circuit, causing the pressure to drop together. When it drops to a certain value, valve 1 closes under the action of the pressure regulating spring, and the pressure no longer decreases (this is known as dynamic closing pressure). At this point, although the pressure at outlet 21 has dropped to zero due to leakage, the remaining three circuits can still maintain normal safety brake pressure and continue to be replenished. This greatly enhances the safety of the vehicle operation.The pipeline directions for the on-site mining vehicle are as follows:21 - Air reservoir - Upper chamber of the main brake valve for the rear axle (first circuit)24 - Air reservoir - Lower chamber of the main brake valve for the front axle (second circuit)23 - Air reservoir - Exhaust valve and auxiliary air for parking brakeThe role of the four circuit protection valve:The four circuit protection valve has the function of a protection closing pressure, which means that after a certain circuit fails, other circuits will not leak when their pressure drops to a certain level and can still perform related operations normally.

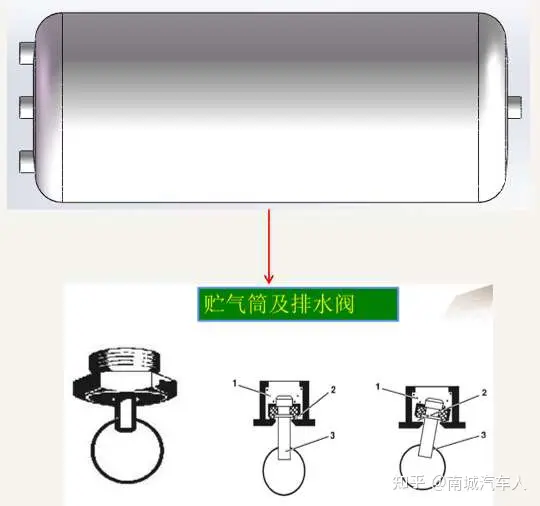

4. Air Storage Tank1. The role of storing gas.2. Filtering function. Relatively heavy impurities such as moisture, oil, and dust in the air circuit will eventually settle to the bottom.3. Exhaust valve. The impurities that settle at the bottom can be released under manual control.4. Filter. The gas passes through the filter to remove any remaining oil and moisture still present in the gas.5. Pressure stabilization.6. Cooling.

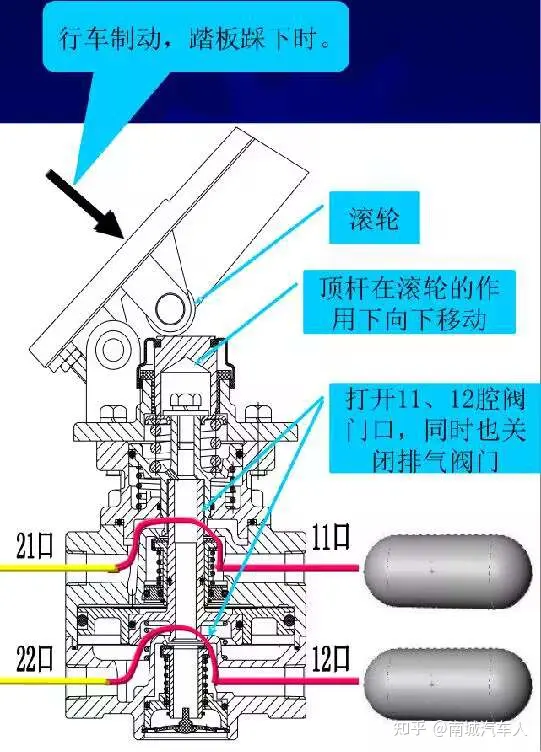

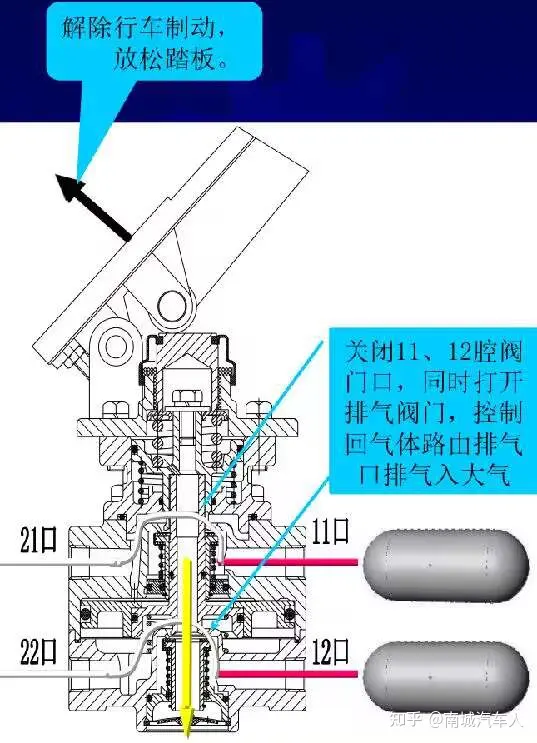

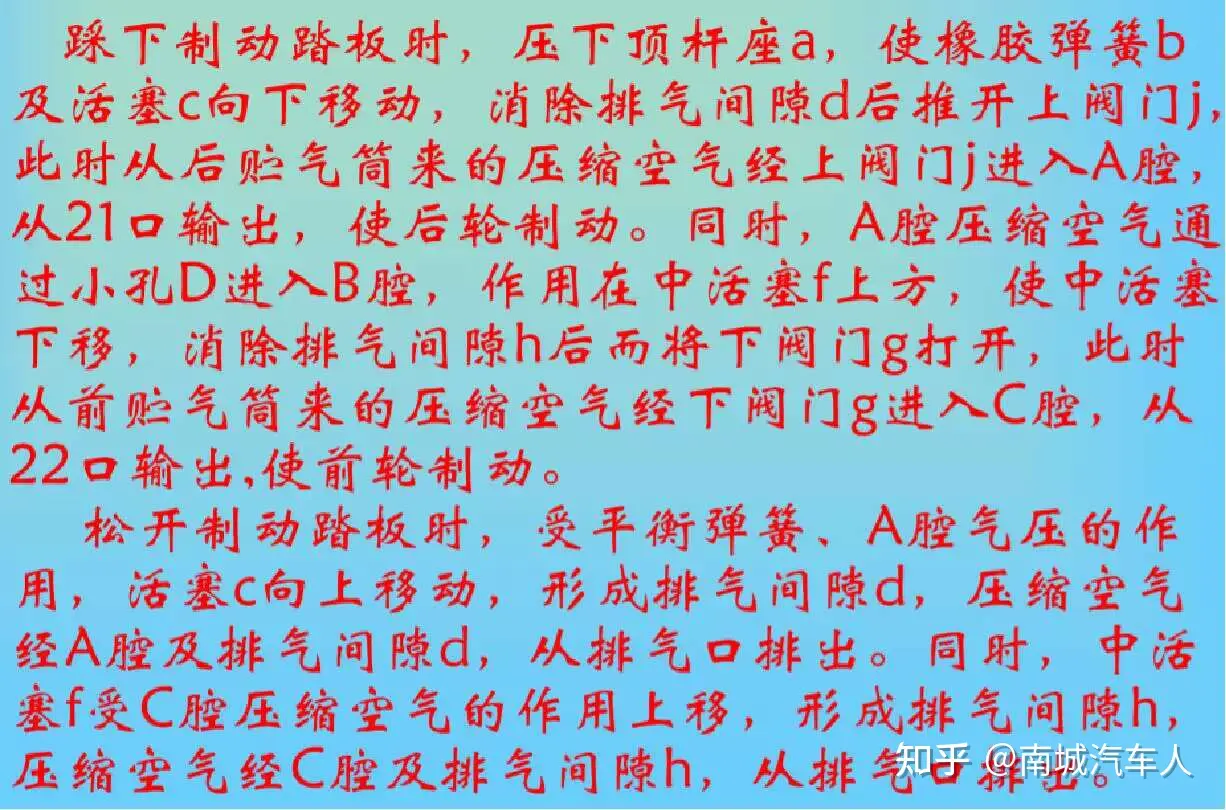

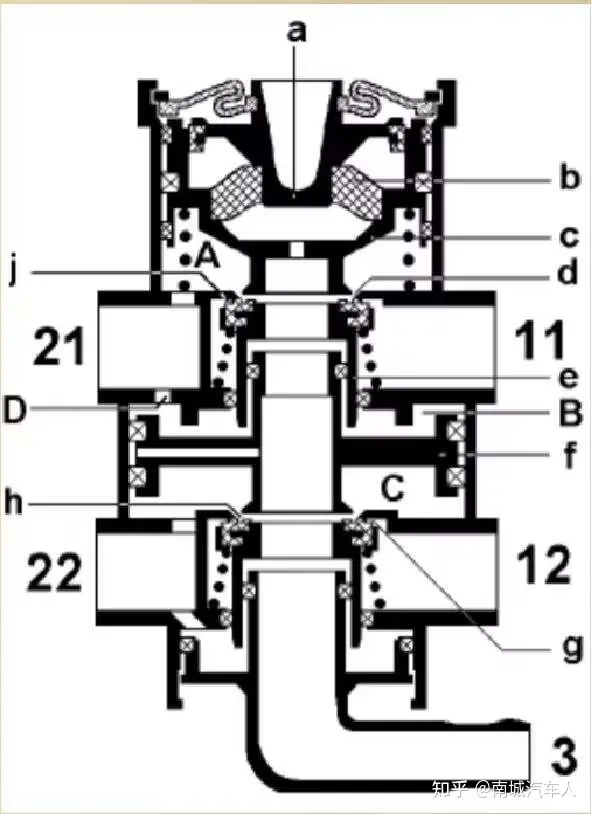

5. Foot Brake ValveDuring operation braking:Press down the main valve pedal, first open port 11, then open port 12, while closing exhaust port 3. At this time, air comes from the air reservoir, passes through port 11 to reach port 21, and then goes through the rear axle relay valve to reach the brake chamber of the middle and rear axles to achieve braking of the rear two wheels. The air coming from port 12 passes through port 22 to reach the front axle relay valve, and then brakes the front wheels through the front brake chamber.

When releasing the parking brake:Release the foot pedal of the main valve, stopping the supply of air from the main valve ports 21 and 22 to the control port of the relay valve. The air in the brake chamber is discharged into the atmosphere through the connected relay valve.

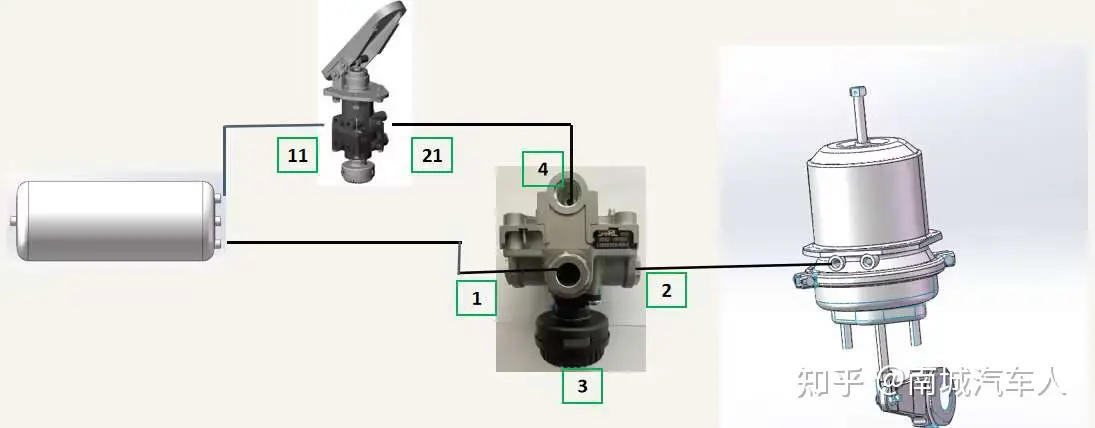

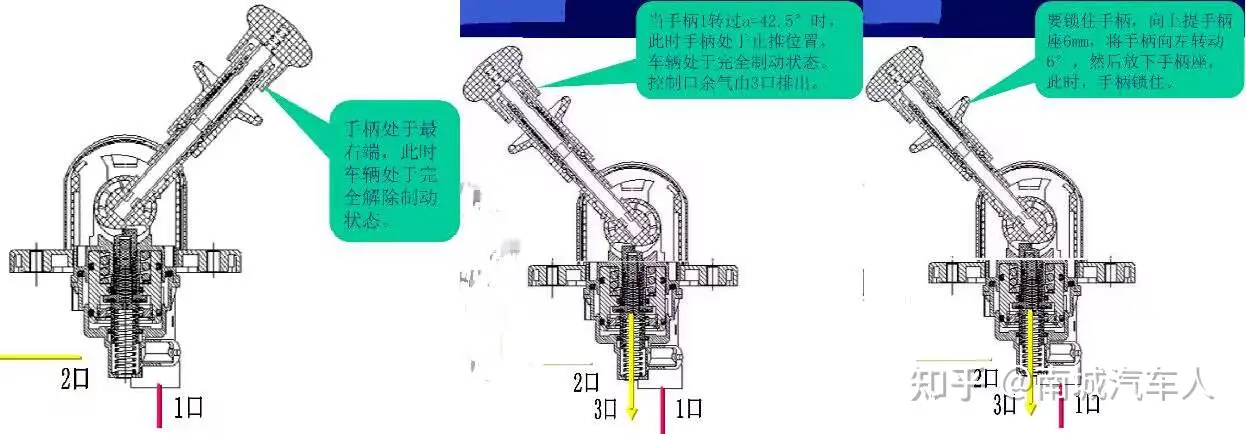

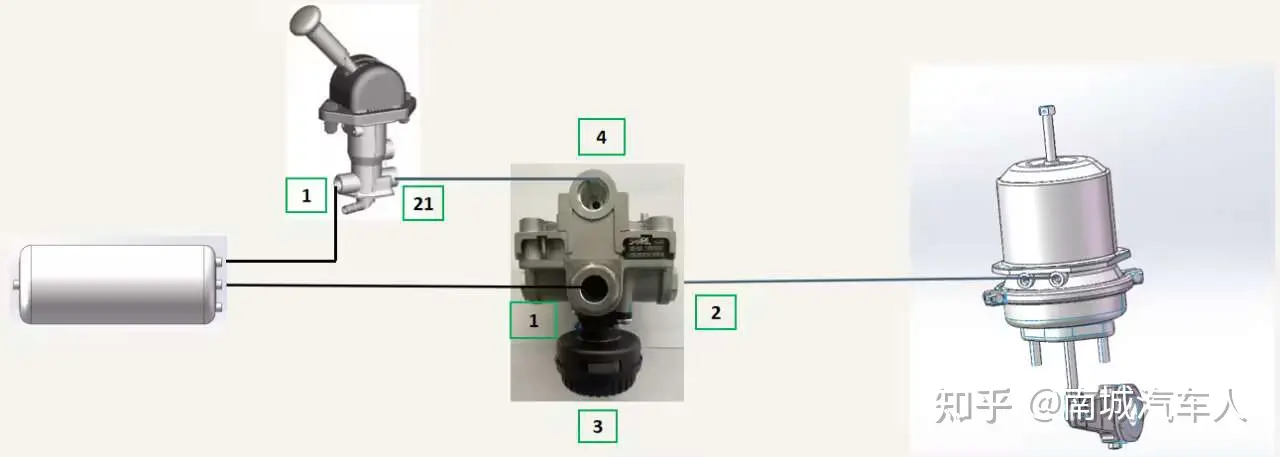

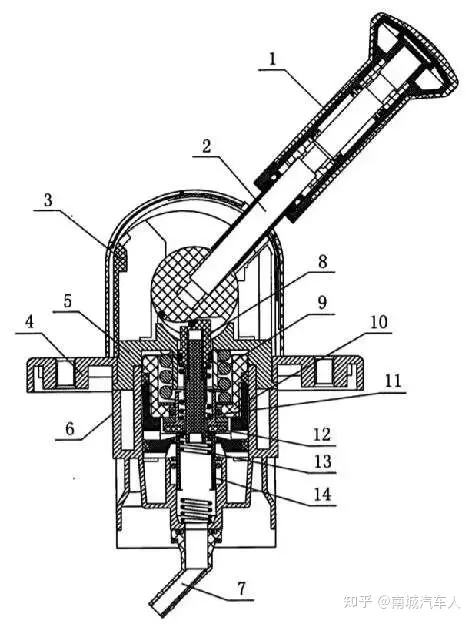

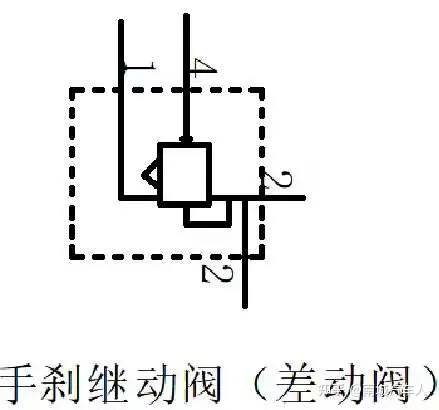

6. Handbrake ValveParking brake, used to control the handbrake continuation valve, thereby controlling the parking brake chamber of the brake air chamber.

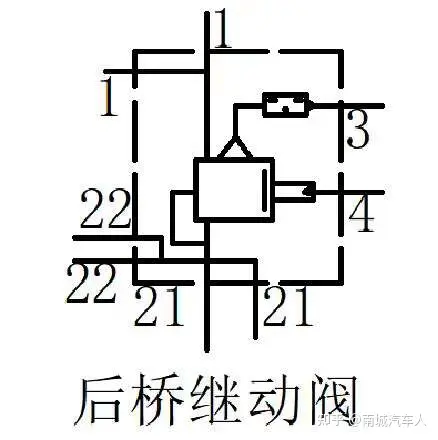

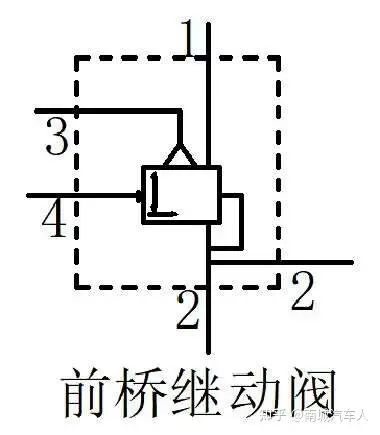

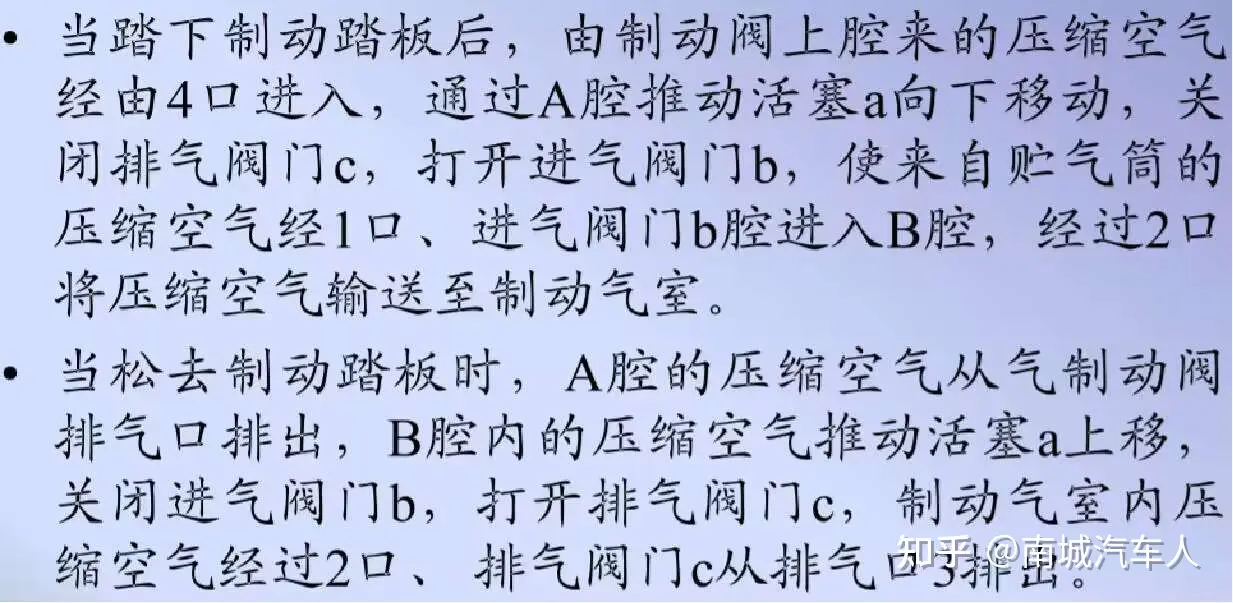

When releasing the parking brake:Release the main valve foot pedal, and the main valve ports 21 and 22 stop supplying air to the control port of the relay valve, allowing the gas in the brake chamber to be discharged into the atmosphere through the connected relay valve.7. Front/Rear Relay Valve1 - Inlet2 - Outlet3 - Exhaust4 - Control Port21 - First Outlet22 - Second OutletThe gas from the foot brake valve enters the relay valve through port 4, pushing the diaphragm of the relay valve down. When the diaphragm moves down, the rubber sealing pad moves down along with the spring, opening the air passage, allowing compressed gas from inside the valve chamber to flow through to port 2 and reach the brake chamber. When the brake is released, the gas at port 4 is disconnected, and the rubber sealing pad and spring rebound due to the lack of air pressure, pushing the diaphragm upward, causing the gas at port 4 to discharge through the pipeline from the foot brake valve at port 3.

8. Front/Rear Auxiliary Valve1 - Inlet2 - Outlet3 - Exhaust Port4 - Control Port21 - First Outlet22 - Second OutletThe handbrake auxiliary valve operates on the same principle as the front and rear axle auxiliary valves. The front and rear axle auxiliary valves are normally closed auxiliary valves, while the handbrake auxiliary valve is a normally open auxiliary valve.

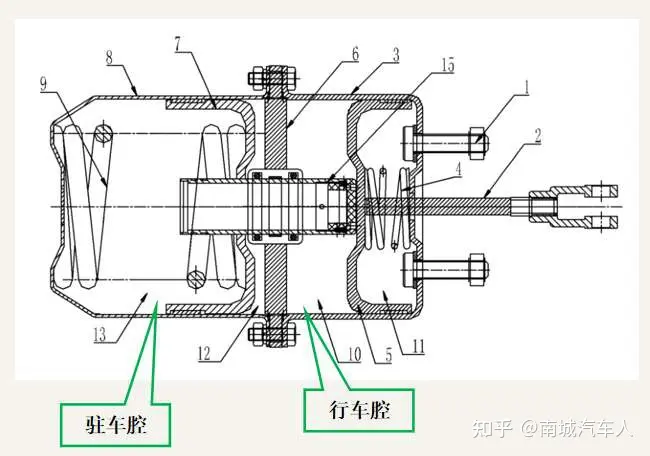

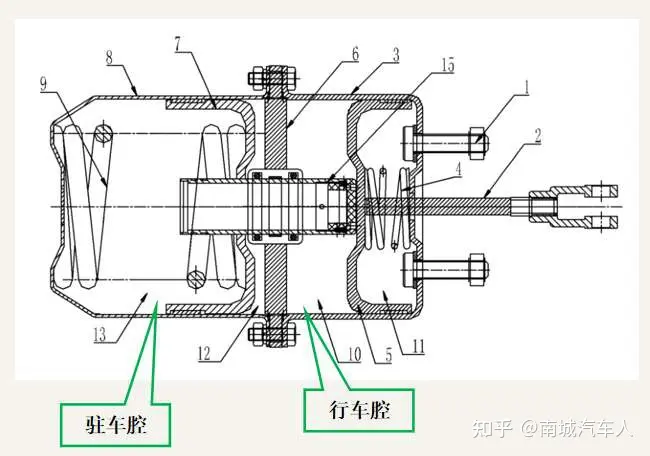

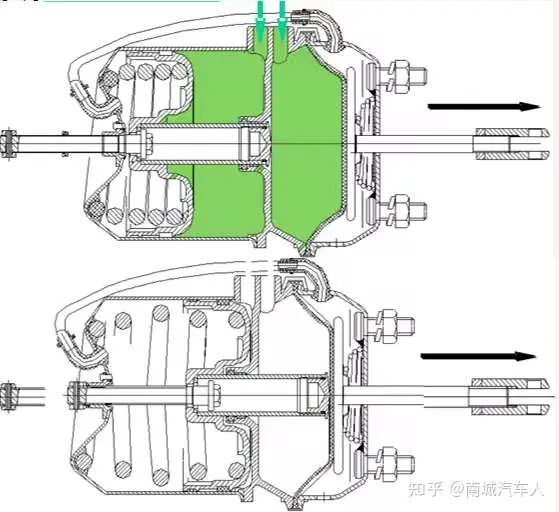

9. Brake air chamber - Service brake30" - Service brake chamber36" - Parking brake chamberService brake: Air from the follow-up valve enters the service brake chamber, pushing piston 5 to the right, which in turn moves thrust rod 2 to the right, compressing spring 4. Thrust rod 2 drives the adjustment arm on the axle, thereby realizing the service brake.Releasing the service brake: When the foot brake valve stops supplying air, spring 4, not receiving pressure, rebounds backwards, moving the thrust rod to the left, which then drives the adjustment arm, thereby releasing the vehicle's brake.

10. Brake Chamber - Parking BrakeParking Brake: During normal operation, there is a certain air pressure in the parking chamber, which compresses the emergency brake spring. When engaging the parking brake, pulling down the handbrake causes the piston in the relay valve to block the air inlet and open the exhaust port. The spring is relieved of pressure and moves to the right, allowing the gas in the chamber to be expelled through the exhaust port of the handbrake relay valve. The diaphragm moves to the right simultaneously, driving the thrust rod to move right, thereby activating the adjusting arm to achieve the vehicle's braking. Releasing the driving brake: Pulling the handbrake valve closes the air circuit, causing the diaphragm in the brake valve to rebound due to lack of pressure. At this time, the air route in the relay valve opens, allowing air to flow into the brake chamber, compressing the spring. The thrust rod, under the action of the spring, pulls back the adjusting arm, releasing the vehicle's brake.

Precautions:a. The product must be installed according to the circuit diagram; do not connect incorrectly, otherwise there may be gas or oil leakage. If a gas leak occurs, promptly check whether all joints are tightened and replace sealing components if necessary.b. The piping must be cleaned before assembly, otherwise it will affect performance and service life.c. The piping should be arranged reasonably and aesthetically during installation.It is most important to understand the working principle of the entire gas and hydraulic system, as well as the function of each interface and the working principles of key components.