26

2025

-

06

Automotive Basics (7) What is a Hydraulic Retarder?

In the previous column: "Automobile Basic Knowledge (6) Why does the clutch have claws?" We detailed the development and classification of clutches. But many people will say, "The automatic transmission of the car does not use this friction clutch, but uses a torque converter." Whether this view is correct or not, let's not rush to conclusions. In this issue, let's first clarify the concept: what exactly is a torque converter? What does it have to do with hydraulic retarders?

● What is the difference between the three types of fluids?

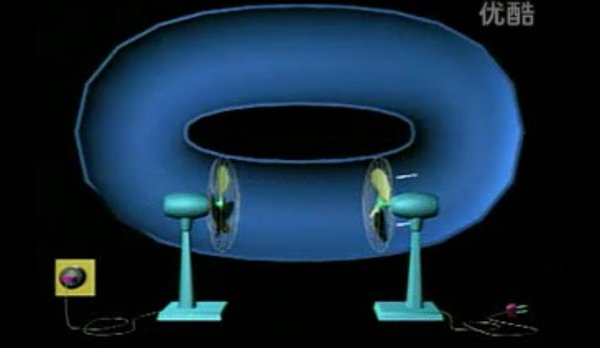

When it comes to fluid couplers, the most common example is two electric fans: two fans stand face to face, and when one is powered on, the other fan will also be blown around. It's very simple.

Fluid couplings

Again, if you put this model in liquid, it will work as well. Then there is a group of little clever ghosts who have come up with some ideas: connect a set of fan blades to the engine flywheel, and then connect a set of fan blades to the shaft of the gearbox, and blow oil in the middle, can't you make the car move? There's no wear and tear that way, how awesome!

So, this wave of people began to refine the model, so that the fluid force inside flows more regularly, minimizes the loss of energy, and then - dangdangdang - the fluid coupling (whether there is a robot cat or not).

Torque converter

At this time, another group of people felt that the fluid coupling was not enjoyable enough, so they made some improvements for him:

First of all, a mysterious device is added, after this device, the greater the difference in speed between the two electric fans, the greater the force on the passive electric fan. This way, the vehicle will have more power when it starts.

Then when the speed of the two electric fans is not much different, install a locking mechanism for him to lock the two electric fans together, so as to reduce energy loss.

Hydraulic retarder

After the students of the transmission department finished their homework, they were seen by the students of the brake department. They also came up with an idea: if I fixed the electric fan behind the fluid coupler to prevent it from turning, the electric fan in front of me would not only not be able to blow it, but would also be resisted. In this way, it was possible to slow down the vehicle - so I quickly borrowed the homework and copied it, and invented a new thing - the hydraulic retarder.

So, to put it simply, the model of a fluid coupler is that an electric fan blows another electric fan around; The torque converter is an amplifier added between the two electric fans, and the larger the speed difference, the harder the blowing; The hydraulic retarder is an electric fan blowing against a wall, and then the wind bounces back and blows on your face, blowing yourself to a stop.

● Several misunderstandings of hydraulic retarder

Now that we know how they work, let's go back and talk about the (relative) accessory commonly used in our trucks, the hydraulic retarder. In the comments on the previous article, I always felt that everyone seemed to have some misunderstanding about him:

First of all, the hydraulic retarder is virtually wear-free. The brake is rubbed against two solid pieces together, while the hydraulic retarder is rubbed with liquid – the equivalent of water skiing. How gentle;

Secondly, not only downhill, but almost all decelerations can be achieved with a hydraulic retarder. It's just another form of braking.

Finally, using a hydraulic retarder may keep the engine revving high, but it doesn't actually cost fuel. There is no fuel injection during the deceleration phase.

● Hydraulic retarder cattle to cattle But not a panacea

Hydraulic retarder can provide safe driving guarantee when used reasonably, but it is not a panacea.

1. First of all, there must be a reasonable speed belt to make it have a good working effect. If the speed of the input shaft is too low, the speed of the turbine will not be reached, and the effect of auxiliary braking will not be too good. Therefore, the liquid slow is not suitable for use at too low speeds.

2. Limitations on the use of liquid slow. Liquid slowing is the conversion of potential energy into heat energy, which is then dissipated into the air through the engine's heat dissipation system. Therefore, there are relatively high requirements for the layout of cooling pipelines, the working efficiency of the engine water pump, and the heat dissipation power of the engine.

The manufacturer's technical recommendation is that if the power is less than 350 horsepower, it is not recommended to install it.

● Several common retarder brands

Voith:

Brands such as Sinotruk and Jiefang use Voith hydraulic retarders when using their own transmissions. At the same time, it is also a supplier of Mercedes-Benz and the originator of hydraulic retarders.

Some time ago, I heard that Voith's liquid slow has higher requirements for heat dissipation, and Sinotruk's machine performs very well in the cooling system, so Sinotruk likes this combination (not confirmed by engineers).

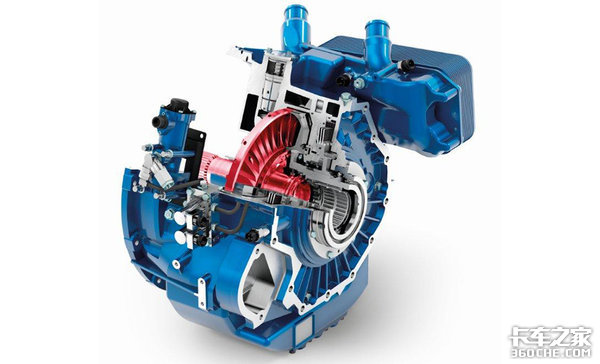

ZF:

ZF's gearbox is basically equipped with its own liquid slow. The manual transmission of SITRAKA, AMT's Foton EST, JAC K7 and so on are all this combination.

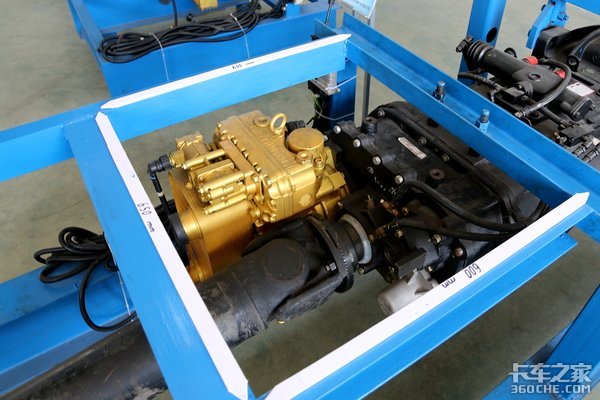

Fast:

Just like upstairs, with your own gearbox. (True Binding)

Scania:

Scania's Liquid Slow is really the best liquid slow in my opinion. After putting it into automatic mode, press the brake pedal, and it will automatically coordinate the hydraulic retarder, brake, and engine braking, and the operation is very worry-free.

Previous Page

Previous Page