25

2025

-

06

Automobile basic knowledge (6) Why does the clutch have claws?

In "Automobile Basics (5) When the "Clutch" Meets the "Double", we talked about the difference between the dual clutch, the double plate clutch, and the dual mass flywheel clutch. But in the comment area, I saw that a few cardholders still confuse these concepts. Coincidentally, my undergraduate graduation project is heavy truck clutch design (although I do it very watery), but I have learned some things, so in this issue, let's talk about clutches separately.

● Development of clutches

Early automotive clutches actually came from other mechanical devices. According to some sources, the clutch of the first generation is a flat belt (personal inference should be the kind of centrifugal clutch on a small motorcycle). However, the transmission efficiency of the belt is too low, and the wear is very serious, especially in rainy days, and the power transmission is prone to problems. As the gears of the gearbox increased, the clutch continued to withstand more torque, so a variety of clutches were invented, including the clutch based on the principle of friction, the pioneer of modern clutches.

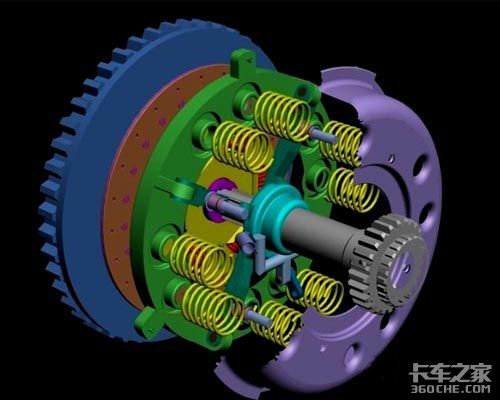

Since the clutch needs to switch between disengagement and bonding, the spring is certainly an essential element. Cardholders with long driving experience know that the previous truck clutches used coil springs, some of which were placed in the middle and some were distributed in the outer ring. The current clutch does not have these springs in it, but instead has a set of discs with claws.

"

The diaphragm spring clutch was born in the research laboratory of General Motors in 1936 and was mass-produced in the United States in the late 30s of the 20th century. In the mid-1950s, it began to be used in a number of single European models. The Porsche 356, BMW 700 and DKW Munga were the first German-made cars to be equipped with a diaphragm spring clutch. Mass production of diaphragm spring clutches began in 1965 with the Opel Rekrod model.

"

In the past few years, the varieties of diaphragm spring clutches have been able to fully cover the domestic demand for heavy, medium, light, car, micro and agricultural models. So, why not use coil springs instead of diaphragm springs?

● Diaphragm springs – more comfortable and reliable

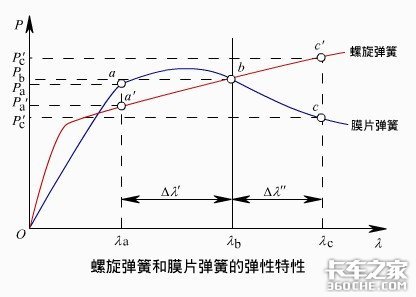

Everyone knows that the tighter the coil spring is pressed, the more elastic it will be – that is, the deeper the clutch pedal is pressed, the harder it becomes. But diaphragm springs are different, they have the greatest elastic force when they are deformed to a certain extent, and then continue to deform, and the elastic force will become smaller - that is, the deeper the clutch pedal is pressed, the heavier it does not necessarily become.

For overloaded vehicles, it is clear that coil springs provide more elastic force to hold down the clutch plates and ensure power delivery. However, for the standard load vehicle, there is no need for excessive elastic force, and if the loading point of the diaphragm spring is selected, it can make the clutch pedal more light and labor-saving while ensuring the compression force, and reduce the driver's fatigue.

At the same time, for coil spring clutches, as the friction plate wears and thins, the spring deformation will definitely become smaller, so the compression force will definitely gradually decrease, but the diaphragm spring will first become larger and then decrease.

(High-energy warning: the following red letters are specific instructions, and those who feel a headache should quickly bypass)

For example, in the picture above: when the clutch is installed, the spring is pressed in the b position; When the clutch is pressed, the spring is pressed to the C position; After a period of wear, the spring returns to position A, at which point:

For coil springs: the force of pressing the clutch pedal will be heavier and heavier; When the clutch plates are worn, the compression force decreases.

For diaphragm springs: the force of pressing the clutch pedal will become lighter and lighter; After the clutch plate is worn, the compression force will increase;

As a result, diaphragm spring clutches are more comfortable and reliable than coil springs.

● Nowadays, the clutch commonly used in heavy trucks is a single-piece push diaphragm spring clutch

As we said in the previous issue, in the early years, in order to transmit more torque, the clutch of heavy trucks would use two friction plates, that is, a double-plate clutch. However, the two friction plates are easy to cause the problem of incomplete separation, so in recent years, with the improvement of material technology, heavy trucks have gradually changed to single-plate clutches.

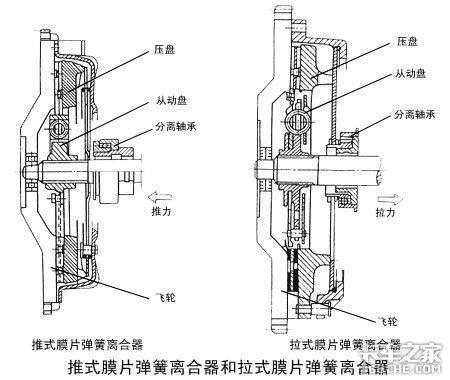

In addition, those who have disassembled the clutch may have seen that some clutches are separated from the bearing after pressing the "claw" in the middle of the clutch, and the clutch will disengage, while some need to disengage the bearing to pull the "claw" outward. These are actually two types of clutches: a pull clutch and a push clutch. The pull clutch claw cone is topped inwards and the push-type is outward.

Due to structural problems, in the case of the same size of the pressure plate, the pull clutch can adopt a diaphragm spring with a larger diameter to provide greater compression force and transmit more torque; Or, for the same torque, a smaller size can be used. Therefore, the tension diaphragm spring structure is more compact, and the advantages are more obvious.

● To sum up: several classifications of clutches

Having said so much earlier, many people may be a little confused, let's make a summary, clutches can be divided into these categories:

1) According to the number of driven discs, the clutch can be divided into single-plate clutch, double-plate clutch, multi-plate clutch, etc.;

2) According to the spring type, the clutch can be divided into cylindrical coil spring clutch, conical coil spring clutch, diaphragm spring clutch, etc.;

3) According to the spring arrangement, the coil spring clutch can be divided into circumferential spring clutch, central arrangement spring clutch, etc.;

4) According to the direction of force, the clutch can be divided into push clutch and pull clutch.

Nowadays, clutch brands such as Eaton and Valeo from abroad have a very high installed capacity in the field of domestic heavy trucks, and domestic Tieliu, Changchun Yidong, Sanhuan and so on also have a very good market share. In addition, with the continuous improvement of material technology, new forms of clutches continue to appear, such as Eaton's "ceramic clutch" launched in 2017 for the harsh working conditions of heavy trucks.

Previous Page

Previous Page