24

2025

-

06

Automobile basic knowledge (5) when the "clutch" meets the "double"

Unconsciously, the "Basic Knowledge of Automobiles" column has done the fifth issue, seeing the affirmation and suggestions given by cardholders in the comment area, the author is really very happy, thank you for your support. From this issue onwards, this column will be fixed every Saturday to meet with you, and you can see the latest content of this column when you get up on the homepage of the Truck Home APP on Saturday morning.

In the last issue, we talked about the drivetrain of the car, and there was a concept called "dual-clutch automatic transmission". In addition to this concept, you may have heard of "dual-plate clutch" and "dual-mass flywheel clutch". These three terms all have two sets of words, "double" and "clutch", but they represent completely different parts.

● Double-plate clutch – two friction plates

A double-plate clutch is actually a clutch with two friction plates.

As we all know, the clutch consists of a pressure plate, a friction plate (also called a clutch plate) and a release bearing. During normal operation, the pressure plate and engine flywheel clamp the clutch plates, transmitting power to the clutch plates, which in turn transmit to the shaft of the gearbox.

Obviously, the amount of torque that can be transmitted by the clutch is limited by its size, so if you want to break this limit, you need to add a friction plate and a medium pressure plate between the two friction plates.

Some early heavy-duty trucks would have adopted this structure, but the two-plate clutch had relatively poor heat dissipation and was prone to incomplete separation. Nowadays, with the upgrading of material technology and the reduction of overload, it is basically a single-plate clutch.

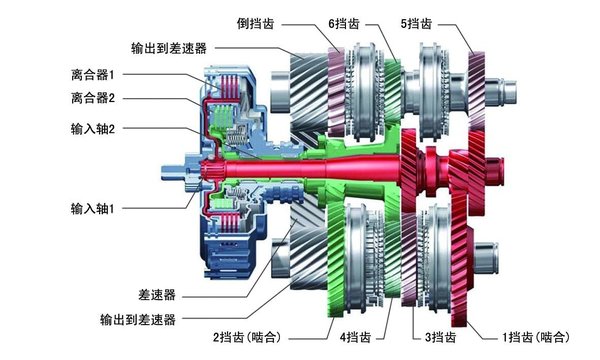

● Dual-clutch gearbox – two clutches

A dual-clutch gearbox is a gearbox equipped with two clutches.

To put it simply, there is a clutch connected to the gearbox's odd-numbered gears (1, 3, 5, 7, etc.), and another gearbox connected to even-numbered gears (2, 4, 6, etc.). This way, when you accelerate in 3rd gear, the gearbox can hook up 4th gear in advance and "press" the clutch corresponding to 4th gear at the same time. When it is necessary to shift gears, "press" the clutch corresponding to the 3rd gear, "release" the clutch corresponding to the 4th gear, and the shift is completed.

Dual-clutch gearboxes were used in racing cars in the early days due to their excellent shift speed. Due to the faster gear shifting speed, the engine idling time will be less, so it has better fuel economy, so it has gradually developed into the field of civilian passenger cars.

In recent years, foreign companies including Daimler, Eaton, Volvo and other foreign companies have begun to launch their dual-clutch products in the field of commercial vehicles.

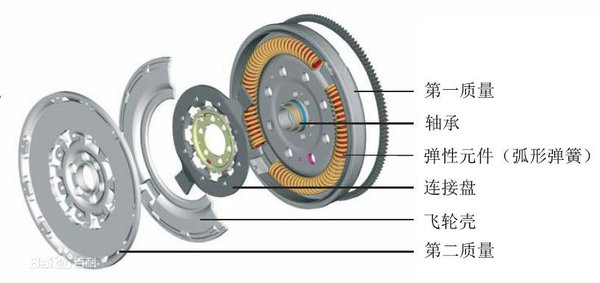

● Dual-mass flywheel clutch – The flywheel is split into two pieces

Cardholders who have removed the clutch know that there is a set of springs in the middle of the clutch plate "torsional shock absorber", when the clutch is combined, it plays a cushioning role, so that the vehicle can start more smoothly.

However, because the first task of the clutch is to transmit power, and the size of the torsional shock absorber is very limited, the spring will generally be stiff - it can only be used to a certain extent at the start. When the vehicle is idling, the vibration of the engine is transmitted to the gearbox through the flywheel and clutch, and due to the principle of "resonance", the vibration of the vehicle is very obvious, which I believe everyone is deeply aware of.

To solve this situation, the automotive engineers decided to take out this torsional shock absorber and place it next to the flywheel, so that it could be made a little larger and a little softer without the clutch plates. At the same time, divide the flywheel into two parts and connect them with this spring. In this way, the power of the engine must first pass through the first mass, then through the torsion spring, then through the second mass, and then transmitted to the clutch and gearbox。

After such a layer of filtration, the vibration will basically stay in the engine, which can not only reduce the overall noise, but also extend the service life of the gearbox, which is more obvious for diesel engines with higher output torque. According to ZF engineers, their Sachs dual-mass flywheel clutch can make the comfort of a diesel car comparable to that of a petrol car.

Well, in this issue, we will mainly talk about these three concepts: dual-plate clutch, dual-clutch transmission, and dual-mass flywheel clutch. The next plan is to talk to you about several classifications and development processes of clutches, I don't know if you are interested

Previous Page

Previous Page