23

2025

-

06

Automobile basic knowledge (4) how to choose a manual gearbox?

In the last article, we talked about the braking system of the car, including the respective advantages of disc brakes and drum brakes, the principle of ABS, etc. (click here to review the braking system of the car, "Automobile Basic Knowledge (3) What is the role of ABS?"). 》)。 In this issue, we'll continue to talk about another major system of the chassis: the drivetrain.

● Review of the previous period

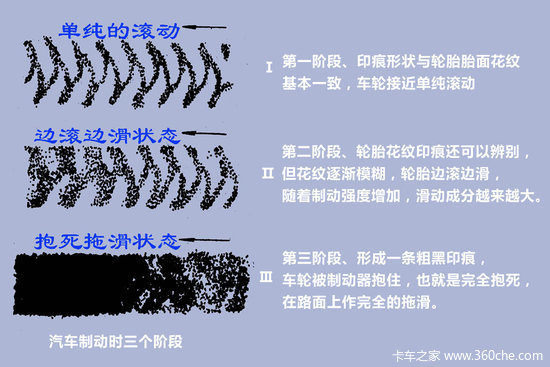

Before talking about the drive train, I would like to discuss a topic with you on the content of the previous issue: some people on the Internet say, "The brakes of cars with ABS should be stepped on to death"; Or someone may say, "ABS only works when the brake pedal is pressed all the way down". Are these two statements correct?

Going back to what we said in the previous issue, ABS is a device to prevent the wheels from locking. That is, ABS comes into play when the wheels are about to lock up – will the wheels only lock when the brakes are pressed? Of course not. When the road is slippery, the brakes are a little heavier, and the wheels are easy to lock up and cause danger, so ABS will work to protect the vehicle.

So, on a normally dry road surface, normal braking, ABS really won't work – because nothing dangerous will happen. ABS is like a seat belt, every time we work, it is because we are in danger. Therefore, the logic of the first sentence above is obviously "there is no danger, and ABS should be used to create danger", which is obviously very undesirable. ABS can only pull us on the edge of danger. Staying safe and not putting yourself in danger is king.

● Composition of the drive train

Okay, let's get started with this issue:

How many steps does it take to put an elephant in the freezer? Oh no, how many steps does it take to transfer power to the wheels?

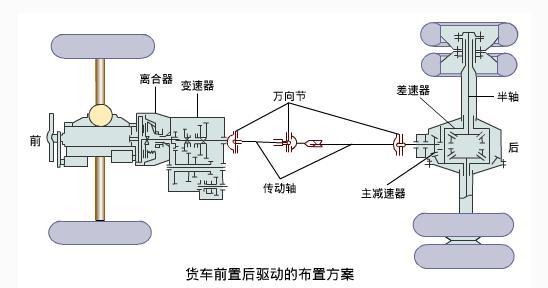

Looking back at the content of the second issue, the power generated by the engine goes through: clutch, gearbox, universal transmission, final reducer, differential, drive half shaft and finally transmitted to the wheels. This makes up our drivetrain. In this system, everyone pays great attention to the gearbox and the rear axle, which contains the final drive, differential and drive half-shaft.

In this issue, we will focus on two components: the gearbox and the differential

● What are the types of gearboxes?

In terms of general categories, transmissions are divided into two types: manual transmissions and automatic transmissions.

The manual gearbox is referred to as MT, and its internal structure is believed to be very clear to many card friends, which is to change the transmission ratio by meshing gears of different sizes.

However, I believe that many novice drivers will have the same question as I used to: Isn't it dangerous to turn the gears so fast and turn them together when changing gears? In fact, the gears in the gearbox are meshed in advance, and the gear shift is "activated" by other mechanisms to the corresponding gear set. And most of today's gearboxes have synchronizers, which can make the ring gear speed of different speeds become the same when changing gears. Let's watch the following video for the specific principle (friendly reminder: the video is long, it is recommended to watch it in a wifi environment):

There are many types of automatic transmissions, such as electronically controlled mechanical automatic transmissions (AMT), dual-clutch transmissions (DCT or DSG), hydraulic automatic transmissions (AT), and mechanical continuously variable automatic transmissions (CVT). The structure of these types of gearboxes is different, and the AMT gearbox is generally used on trucks, while the other three are more on sedans. To learn more about their differences, check out my previous article: Don't get confused! Although they are all automatic transmissions, the difference is huge." Here are a few conclusions from that article:

1. The automatic transmission used on the truck is AMT, which is not common in small cars;

2. Many engineering heavy-duty vehicles will use AT, because the torque converter is more reliable than the clutch in the case of heavy-duty starting;

3. In addition to the cost problem, there is also a reason that the AT gearbox is too few gears, which cannot take into account the two working conditions of heavy load and high speed;

4. Volvo's I-shift gearbox has a dual-clutch version;

5. These automatic transmissions (including CVT) can be "manual automatic", that is, they can change gears automatically or manually. It is not a configuration unique to "AMT".

6. Although the previous article is correct, most vehicles equipped with CVT transmissions do not support this function.

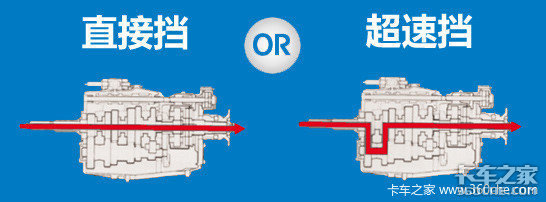

● How to choose direct gear and overdrive

According to the structure of the gearbox, we know that the input shaft and output shaft of the gearbox can be directly connected through a gear to output power, and the input speed and output speed are the same, we call this gear a direct gear. The other gears of the gearbox need to transmit power through the countershaft of the gearbox. Comparatively, the direct transmission process is shorter and the energy consumption is less. Therefore, if the direct gear is the most commonly used gear for everyone, then it will help the fuel economy of the vehicle to a certain extent.

For long-distance trunk tractors, the most commonly used is obviously the highest gear. Therefore, cardholders who pursue low fuel consumption can choose a direct gearbox with a small speed ratio rear axle.

But this combination puts a greater load on the drivetrain. Therefore, if you often run on roads that are not in good condition and pull too hard, then it is recommended that you switch to a high-ratio rear axle with an overdrive gearbox, so that the drivetrain will be more reliable and durable.

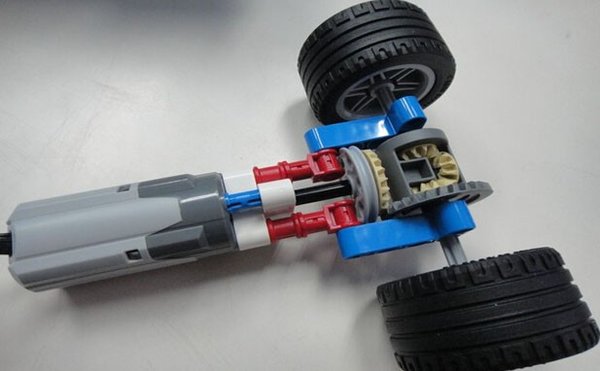

● What is the principle of the differential?

When the vehicle is turning, the outer wheels are bound to be faster than the inner wheels. For the driven wheel, in this way, there is no connection between the two wheels, and the wheel speed can be adjusted by itself, there will be no problem, but how should the driving wheel ensure the power output while also allowing the speed difference between the two wheels? That's where the differential comes in.

For a glimpse into how differentials work, check out the video below (you can start at 3:30):

In other words, the differential is a "soft bone", the side with high resistance will turn slowly, and the side with low resistance will turn faster. Although the bones are soft, they can still continue to transmit the power transmitted by the final reducer.

But some road conditions can bully this soft bone: if one wheel slips and the other wheel does not slip at all, then the slippery wheel will move forward rapidly, and the other wheel will stop and be lazy - the car will lie down. Therefore, vehicles that require off-road ability will have differential locks to fix this "soft bone" - power is evenly distributed on both sides, and no one can be lazy. That's when the vehicle can get out of trouble.

Previous Page

Previous Page