09

2025

-

10

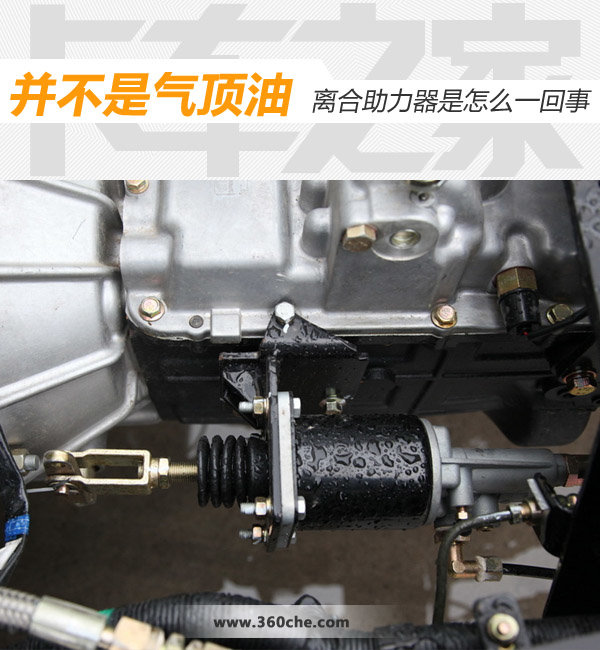

It's not about air pressure or oil. What's going on with the clutch booster?

Some trucks, especially medium and heavy trucks, have clutches with relatively high pressing force. To reduce the effort required by the driver to press the clutch pedal, a clutch booster, also called a clutch assist cylinder or booster pump, is usually used. This device uses both a pneumatic cylinder and a hydraulic cylinder, so some truck enthusiasts may think it works similarly to the principle of air-over-hydraulic brakes. In fact, the principles of the two mechanisms are quite different.

The clutch mechanism uses brake fluid as a medium, starting from the clutch pedal and ultimately transmitting force to the clutch fork, acting on the release bearing to press down the pressure plate diaphragm, thereby separating the pressure plate and clutch disc, interrupting the transmission.

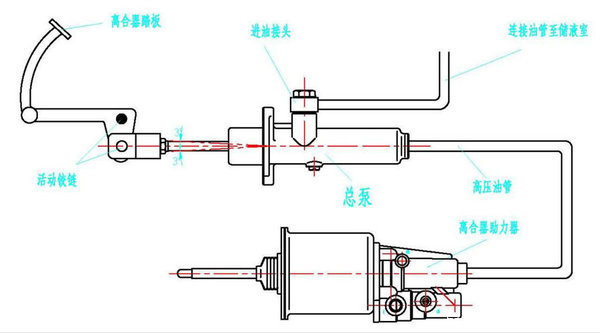

General non-assisted hydraulic clutch mechanism:

Pedal — Clutch master cylinder (hydraulic) — Oil pipe — Clutch slave cylinder (hydraulic) — Clutch fork

Clutch mechanism with clutch booster cylinder:

Pedal — Clutch master cylinder (hydraulic) — Oil pipe — Clutch booster cylinder (hydropneumatic) — Clutch fork

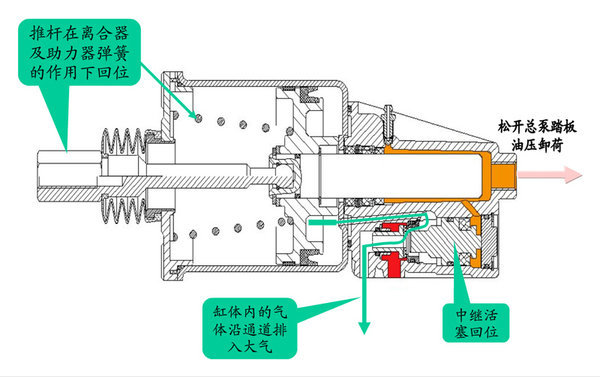

It can be seen that the clutch booster cylinder replaces the original ordinary clutch slave cylinder, but both serve the same function, which is to control the clutch fork through the push rod. However, the booster cylinder introduces a cylinder that uses air pressure to provide assist.In terms of structural principle, the clutch booster cylinder is similar to the pneumatic-hydraulic booster cylinders used in industrial manufacturing. It also integrates a cylinder and an oil cylinder, with hydraulic oil and compressed air kept separate, using compressed air to achieve the boosting effect.

Pressing down the clutch pedal causes the clutch master cylinder to output brake fluid to the oil chamber of the booster cylinder. At this time, the hydraulic oil has two paths: one is to push the master cylinder piston connected to the push rod, and the other is to push the servo piston, opening the cylinder valve and allowing compressed air from the air reservoir to enter the air chamber of the booster cylinder. Under the combined action of air pressure and hydraulic pressure, the push rod is then pushed out. Releasing the clutch pedal causes the oil pressure to drop. Under the force of the clutch pressure plate spring, the push rod moves back to its original position, and the servo piston also returns simultaneously, closing the intake channel. At this time, there is an exhaust gap between the valve assembly and the servo piston, allowing compressed air to be discharged into the atmosphere, and the push rod returns to its original position.

Unlike a vacuum booster pump, the clutch booster pump provides assistance more directly. In addition, for some small truck drivers who want to install a clutch booster pump, there are two things to pay attention to: first, there must be an air storage tank (mandatory for air-brake models), and second, there must be enough installation space. On the market, clutch booster pumps come in cylinder diameters ranging from 70mm to 120mm, and small trucks generally use pumps with smaller diameters.● Editor's Note:Some people might say, wouldn't it be better to use air pressure directly for the clutch? However, from using air brakes, we can feel that air pressure is not very controllable, and the clutch requires semi-clutch control, so using pure air pressure is not very practical. In summary, air-over-hydraulic brakes operate through a series connection of an air chamber and a hydraulic cylinder, with hydraulics performing the braking action, while a clutch booster cylinder is an air-liquid integrated component that uses air pressure for assistance. Therefore, clutch assistance cannot be called air-over-hydraulic.

Previous Page