08

2025

-

10

The dual-chamber airbag seems inconspicuous, but poor maintenance turns it into a ticking time bomb.

When it comes to dual-chamber brake chambers, many people are still unfamiliar with this term. However, when mentioning one of the components inside the brake chamber, the 'diaphragm,' it becomes much more well-known. Structurally, heavy-duty vehicles differ from smaller vehicles. Due to their own weight and strong inertia, they rely on the powerful braking force of pneumatic brakes during parking, resting, and deceleration. Today, let's take a closer look at the ins and outs of brake chambers.

▎Real Case: No Serious Danger

Today, while chatting with a veteran driver, we discussed this year's transportation market and I also asked about the issue with the air chamber 'diaphragm'. Now I’m sharing this real case with fellow truckers. Master Zheng's home is right next to National Highway 319, which provides great driving convenience. Every time he finishes loading cargo and returns home, he parks the truck at his doorstep, and only reverses it out when it's time to head out for unloading.

So the problem lies here: the road from the house to National Highway 319 has a certain slope, and every time the vehicle backs out, it requires some braking force. At around 1 a.m. on a certain day, Master Zheng, as usual, started the car, inflated the tires, tapped the tires, and checked the chassis. Once all preparations were done, he began to back out. After pressing the brake twice, the brake suddenly became soft. He pressed it several more times, but it was ineffective. In an emergency, Master Zheng pulled the handbrake. Fortunately, the vehicle slid only a short distance before stopping, with the rear wheels hitting a stone at the edge of a ditch. It was a narrowly avoided disaster. At that moment, another coal truck was passing in the same direction, but fortunately, the other driver changed lanes to avoid a collision.

Regarding this issue, after the mechanic came, it was found that the diaphragm of the brake chamber was damaged and leaking air, which caused brake failure. After replacing it, everything returned to normal. Here, I want to emphasize an important point: the real name of this 'diaphragm cup' is actually the diaphragm, but people are more accustomed to calling it by its nickname. Next, I will introduce the overall structure of the brake chamber.

▎Types and Principles of Brake Chambers

'Which vehicles need to be equipped with brakes?' Here, I want to address a question from truck drivers. According to the national mandatory standard GB7258-2017, all wheels of motor vehicles (except three-wheeled vehicles) and trailers (except trailers with a total mass not exceeding 750kg) must be equipped with brakes. They are also divided into traditional hydraulic brakes and air brakes, with vehicles equipped with brake chambers falling into the air brake category.

Principle: During the braking process of a truck, compressed air pushes the diaphragm (air cup) inside the brake chamber, which in turn drives the push rod to rotate the cam by an angle through the adjuster arm. The cam is eccentric, and as it rotates, it causes the brake shoes to expand and rub against the brake drum, creating resistance and achieving the vehicle's braking effect.

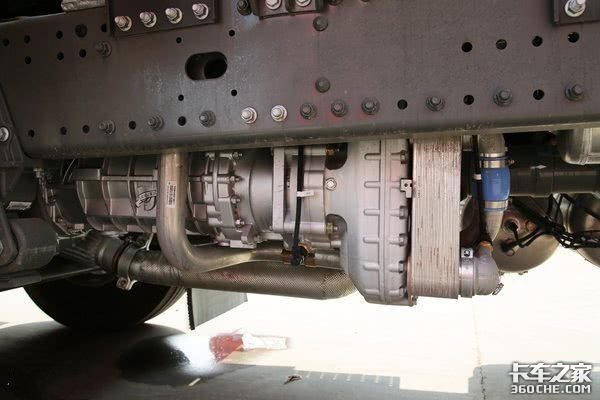

Among them, the truck's brakes are also divided into service brakes, parking brakes, and auxiliary brakes. What are the differences between them? Service brakes: Service brakes are divided into single-chamber brake actuators and dual-chamber brake actuators. From the design principle of the vehicle, the braking force of the front wheels needs to be less than that of the rear wheels to prevent loss of control during emergency braking. Therefore, the front wheels responsible for steering only have one service brake sub-cylinder. This type of sub-cylinder is a single-chamber brake actuator that is only activated during service braking. It has the advantages of a simple structure, compact size, and easy maintenance. You can take a look at the small package next to the front wheel.

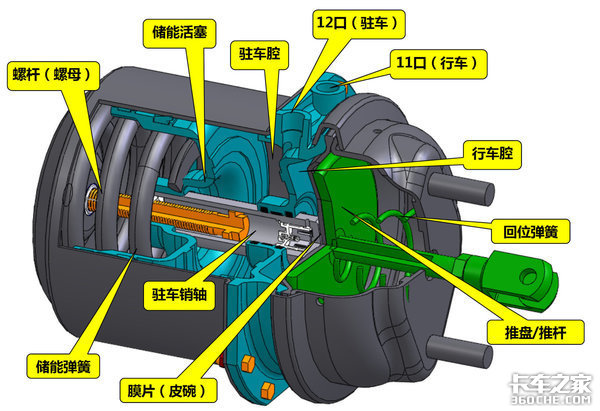

Parking Brake: Most highway freight vehicles are rear-wheel drive, though four-wheel drive vehicles may be used for mountain climbing needs, such as transporting logs or stones. Axles that handle driving and heavy loads generally use larger dual-chamber air brake chambers, which provide stronger braking force. Structurally, a dual-chamber air brake is essentially a single-chamber air brake with an additional chamber. Of the two chambers inside, one is responsible for service braking while the other is for parking braking. This setup can be operated according to practical scenarios and is commonly found on drive axles and trailer axles.

The role of the dual-chamber air brake is indeed significant, and its structure is not complicated. It consists of two air ports, which are connected to the service chamber and the parking chamber, respectively. You can see the two small tubes extending from the top, which need to be well protected. These are the air passages of the brake chamber, and any air leakage must be avoided. Afterwards, air can be charged or released in different chambers according to different needs to complete the required operations. Auxiliary braking: It is called auxiliary braking because it works in conjunction with the brake chamber. Common examples include exhaust brakes, in-cylinder brakes, and hydraulic retarders, with the best effect being the hydraulic retarder, which can replace brake water spraying. For more details, you can visit http://www.360che.com/news/210611/162731.html to learn more. The author has provided an introduction and comparison there.

Key point to note: Here, if people confuse service brakes with parking brakes, it can also be understood that the service brake is an 'air-on brake,' while the parking brake is an 'air-off brake.' The name 'air-off brake' is quite significant. Through a powerful spring inside the brake chamber, compressed air during driving pushes the spring up. When the handbrake is applied, releasing the air allows the spring to lock the brake. Therefore, even during driving, low air pressure can produce a braking effect. Compared to conventional handbrakes, which achieve parking braking by locking the drive shaft, some vehicles are equipped with a mechanical handbrake in an air brake system, leading to a situation where there is a brake chamber but no air-off brake. When using the foot brake, compressed air also works through the brake chamber. However, if the handbrake or drive shaft fails, the parking brake will fail. In contrast, for an air-off brake, even if any component such as the air pump, piping, air tank, or brake valve fails, the service brake may fail, but the parking brake will still function to stop the vehicle and avoid risks.

Many overloaded vehicles, when their service brakes fail, will achieve deceleration by indirectly loosening and tightening the air brakes. However, under no circumstances should the air brake be locked directly, as this can cause the vehicle to lose control. Similarly, indirectly loosening and tightening the handbrake should not be done too frequently. In principle, this operation causes rapid air loss, and once the air pressure is depleted, it becomes ineffective. In emergencies, it can only be used as a temporary measure. ▎What is the failure rate of brake chambers?As the saying goes: 'Knowing how to drive but not how to maintain your vehicle is useless.' Nowadays, vehicle upkeep requires not only driving skills and sourcing goods but also understanding the vehicle's maintenance cycle, performing regular inspections and replacements of parts, and ensuring stability on the road. This is a key factor for driving safety. So, what precautions should be taken for this dual-chamber brake system that combines service brakes and parking brakes?

Under normal circumstances, the failure rate of a single-chamber air brake is very low, and a dual-chamber air brake is not easily damaged either. Usually, people have heard of repairing brake master cylinders, but rarely about repairing brake wheel cylinders. At most, poor spring quality may lead to the brake pedal not returning to its original position, causing the vehicle to drag while braking. However, if the parking chamber's energy storage spring fails, it will reduce the vehicle's parking capability, making it unable to lock the wheels properly and causing the vehicle to roll. This issue is far more serious than a handbrake line leak, which at most results in loss of air pressure, causing the wheels to lock and making the vehicle unable to move. If the diaphragm (the 'rubber bowl') is damaged, it can lead to situations like what Master Zheng experienced, weakening the braking effect and causing brake failure. Damage to the dual-chamber air brake diaphragm can also prevent the parking brake from fully releasing, causing severe wheel dragging, and even tire tread damage.

It is important to note that the energy-storing springs inside the brake chambers provide braking force for the parking brake and do not rely on compressed air. Therefore, in order to provide sufficient braking force, the energy-storing springs in the brake chambers are extremely powerful. Never attempt to repair a brake chamber with an energy-storing spring by yourself. If you notice any issues, you must wait for professional maintenance personnel to handle it to avoid accidents caused by improper operation.

Regularly check the vehicle for air leaks. If, after parking the vehicle, the air in the air tank is completely gone in less than half a day, this indicates a serious air leak problem, and the air system should be carefully inspected at a repair shop. Do not take it lightly. Additionally, in the quiet of the night, you can also listen closely to the vehicle. Gas leaks often produce a faint 'hissing' sound. As a professional truck driver, your hearing should be much more sensitive than that of ordinary people.

In summary, the failure rate of the brake chamber is not high, but it still must not fail. As the saying goes, pulling one hair can affect the whole body—once the brake chamber malfunctions, it becomes a fatal problem. In current operating conditions for standard-load transportation, most driving occurs on highways, so the frequency of braking is relatively low. It is still recommended to test the brakes a couple of times before going down a steep slope; if there is a problem, you can downshift in advance to decelerate.Truck structures are astonishingly intricate, and the failure of any single component can immobilize the vehicle. Therefore, whether driving or parked, attention must be paid to every movement of the vehicle. Vehicle malfunctions often have certain warning signs; timely detection and repair can prevent accidents. Additionally, the driver’s emergency response is very important. From Master Zheng’s case, it is evident that if the driver is a novice, panic can prevent them from thinking to engage the handbrake or control the vehicle’s direction to use rear obstacles for resistance. The saying 'a fall into a pit makes you wiser' holds true—experienced drivers gain their skills through practice.

Previous Page