18

2025

-

09

Essentials: Common faults and solutions for trailer braking systems

With the rapid development of road transportation, the high load capacity, economy, and efficiency of semi-trailer trucks have attracted industry attention and gradually become the main type of vehicle for long-distance logistics.

Many drivers who are new to semi-trailers lack understanding of the structure, design, maintenance, and upkeep of the semi-trailer. When the braking system malfunctions during operation, they often feel helpless, which can even lead to serious accidents.Apart from mechanical reasons related to the axles and adjustment arms, many faults are caused by issues in the braking air circuit. Today, let's take a look at the common faults and solutions of the air circuit in the semi-trailer braking system:● Composition of the trailer braking system.

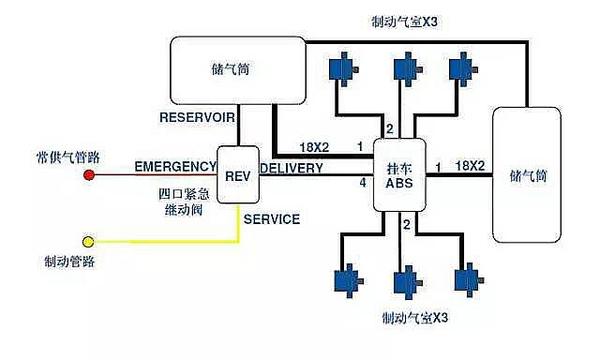

The trailer braking system is generally air-operated, with the air supply coming from the tractor. First, let’s take a look at the schematic diagram of the trailer air system. As seen in the diagram below, the air system of the semi-trailer is not complicated, mainly consisting of three major components: the emergency relay valve, the trailer ABS, and the brake air chamber. In a case where there is no air leak due to improper sealing, most issues arise from these three major components. Of course, problems can be multifaceted, as all air brake-related components can have varying degrees of impact, so caution is necessary during installation. ● Installation requirements for the air system.

Apart from the three big components, the installation of the air system is also very important. It may seem basic, but if not done properly, the vehicle's performance will not be satisfactory.

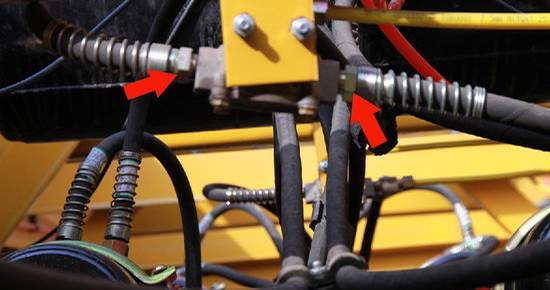

The air circuit connection should not have any unnecessary twists and turns; a qualified air circuit is generally straightforward and clear. Additionally, the inner diameter of the air pipes and joints in the air circuit must also meet standards. If not, the braking effect will be compromised. An air circuit that is completed according to requirements not only has superior braking performance and a lower failure rate but also facilitates future maintenance and after-sales, achieving multiple benefits. ● Common faults and troubleshooting methods.

After understanding the structure of the braking system, let's look at some common faults that occur in practice. The braking faults of semi-trailers generally manifest as: air leaks, dragging brakes, and lock-ups! We will analyze them separately below.Fault phenomenon 1: Air pressure is consistently below 0.7 MPa, or there is a noticeable dragging brake phenomenon while the trailer is in motion.Handling methods:1. Replace the tractor to rule out any faults with the towing vehicle.2. Check for air leaks using soapy water to eliminate possible faults such as "leaks at the handshake connection," "leaks at the pipe joints," "air leakage in the brake chamber," "air leaks in the emergency relay valve," and "air leaks in the trailer ABS valve."

If the air leakage phenomenon still exists, it is necessary to check whether water has entered the valve body or if obvious rust can be seen. The occurrence of this phenomenon indicates that the filter and drying effect of the trailer air pipe are poor, and the valve body may need to be replaced.Failure phenomenon two: The trailer cannot start after being parked, and is always locked.Handling method:1. First, unplug the ABS spiral wire to see if it can start normally, in order to rule out circuit issues.

2. Set the tractor to the inflation state, unplug the air hose from the hand control valve, and check whether the air pressure at the "outlet" is normal (the air pressure should be very high in the inflation state).3. Check whether the parking brake is in the released state.4. If there are no issues with the air system, the final inspection should be for mechanical faults in the axle.

The braking system of the trailer maintains the smoothness of the air supply lines in all braking states in terms of safety design. The foot brake and parking brake measures of the tractor work effectively by supplying air to the control lines.Now, an increasing number of customers are modifying the air circuits of their trailers themselves. Due to improper modifications, the original braking system is damaged, and combined with misuse, this has led to many safety and quality accidents. Here, it is necessary to remind vehicle owners that modifications must be carried out at a regulated modification facility or by the original manufacturer.

Previous Page

Previous Page