05

2025

-

09

The double chamber brake split pump only today knows how it works

In our country's medium and heavy-duty truck market, brake types can be said to be diverse, whether it is the pneumatic disc brake popular in Europe and forced by domestic regulations, as well as the practical pneumatic wedge drum brake of FAW Jiefang J7 and other manufacturers, or the pneumatic camshaft drum brake that has been popular in the domestic truck market for decades.

It is inseparable from a key point, air braking. Compared with the hydraulic brakes commonly used in passenger cars, although air brakes require the installation of air compressors, air storage tanks, and various air pressure valves, the overall structure is extremely complex and bulky, the cost is high, and the noise is large.

However, it provides a large braking torque (the average braking torque of a single axle is more than 30,000 Nm, and the peak braking torque can reach 50,000 Nm). It ensures the absolute position of pneumatic brakes in the heavy truck market.

▎What is a brake split pump?

The key component that converts the energy of compressed air into mechanical energy for braking is the brake air chamber, also known as the brake sub-pump in the industry. Our national standard GB7258 strictly requires that every axle must have a brake system.

For 4×2 front-mounted rear-wheel drive two-axle trucks with a total weight ≤of 18 tons of conventional vehicles and cargo, the front steering axle is generally equipped with a single-chamber brake chamber with only brake and braking functions, while the rear drive shaft is equipped with a dual-chamber brake chamber with both braking function and parking function.

According to the national standard "GB/T5620 Road Vehicles, Automobiles and Trailers, Brake Terminology and Definitions", the single-chamber brake air chamber installed on the front steering shaft is called the service brake actuator, which refers to the device that provides driving force to the brake through compressed air in the vehicle driving brake system.

There is also a parking brake actuator, which refers to a device in the vehicle braking system that provides driving force to the brakes through mechanical means such as energy storage springs to keep the stopped vehicle stationary.

The standard name of the rear axle-mounted dual-chamber brake chamber is the spring brake actuator, which is defined as "a combination unit of the driving brake chamber and the parking brake chamber." ”

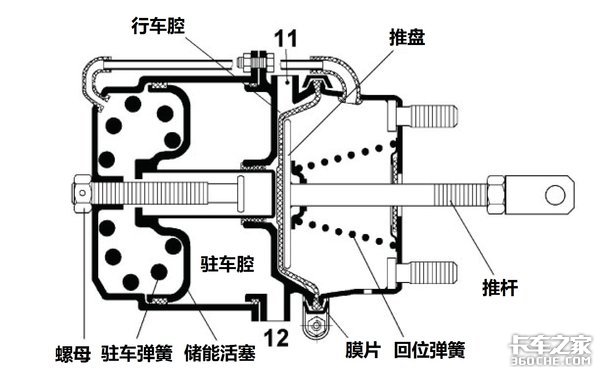

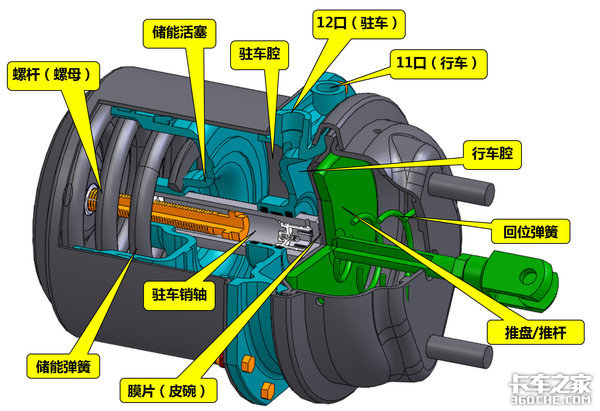

The double-chamber brake sub-pump, that is, the energy storage spring brake air chamber, can realize both driving braking and parking braking, and is widely used in drive shafts and trailer axles, and its structure is slightly more complex than that of single-chamber driving brake air chambers. Combined with the cross-section of the energy storage spring brake air chamber, we make a brief analysis of the working principle:

The compressed air interface of the energy storage spring brake air chamber will be clearly marked with "11" and "12", which is convenient for us to identify the interface type. Among them, the "11" interface is the driving brake interface, which is connected to the driving cavity of the brake chamber; The "12" interface is the parking brake interface, which is connected to the parking cavity of the brake chamber.

We must clarify the concept that the driving brake is "ventilation braking" and the parking brake is "air-cut braking". For clarity, we first isolate the work of the "11" interface and the "12" interface, that is, temporarily isolate the work of the two brake cavities for everyone to understand.

Driving cavity braking: "11" interface inputs compressed air, compressed air finally reaches the driving cavity, and the diaphragm (leather bowl) at the front end of the driving cavity is subjected to air pressure, pushing the push disc and push rod forward to output braking force. Eventually, the push disc/pusher is pushed out to complete the driving brake;

Driving cavity release: "11" interface disconnects compressed air, affected by the return spring, the diaphragm (leather bowl) and push disc at the front end of the driving cavity are returned to their original position, and the driving cavity brake is released;

Parking cavity brake: the "12" interface disconnects the compressed air, the energy storage spring is completely released, and the energy storage spring pushes the energy storage piston, parking pin shaft, and diaphragm (leather bowl) forward to move forward to output braking force, which finally leads to the push disc/push rod to complete the parking cavity braking;

Parking cavity release: "12" interface inputs compressed air, the parking cavity is filled with compressed air, the air pressure pushes the energy storage piston backward, and the parking force brought by the parking cavity air pressure is greater than the elastic force provided by the energy storage spring, and the energy storage spring is once again compressed to the end of the brake air chamber.

At this time, a series of transmission parts such as parking pin shaft, diaphragm (leather bowl), push disc/push rod are returned to their original position under the pressure of the return spring, and the parking cavity is released from the brake.

Let's assume a scenario, sort out the working state of the following brake chambers in the order of "parking→driving→parking", namely: the process of parking release→ driving brake→ brake release→ parking brake, and draw the following schematic diagram for everyone to understand.

In order to avoid the possibility of double braking of the driving cavity inflatable brake and the parking cavity air shutdown brake (the braking torque after the two brakes are superimposed is extremely large, which will cause the brake chamber and all downstream brake parts to fail in the early overload), a differential relay valve is designed on the compressed air pipeline to avoid the simultaneous superposition of the two brakes.