26

2025

-

08

Air pressure not showing? Old driver: The dryer tank should be changed earlier

There are two forms of brake systems on vehicles: oil brakes and air brakes, while most of them are mainly air brakes on trucks. Because the air brake system is characterized by responsiveness, high air pressure and high power, it is suitable for braking trucks.

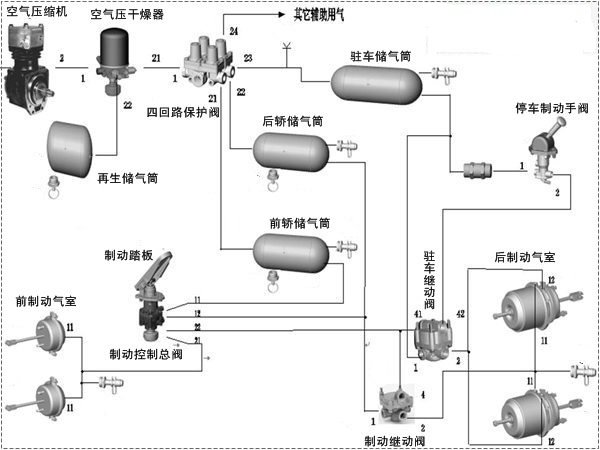

Schematic diagram of the principle of air brake braking

The air brake braking process is that after the gas comes out of the air compressor, it enters the air dryer assembly, and after being dried, it passes through the gas reservoir and various valves, and finally enters the brake air chamber. When the vehicle needs to brake, press the brake pedal to perform the braking process.

▎Two common faults of the air brake system Excessive moisture and air leakage in the pipeline

Excessive moisture will cause damage to parts, such as: when there is too much moisture in the gas tank, it will cause corrosion of the air pressure sensor connector, damage to the air pressure sensor, and cause the failure of the air pressure display on the instrument cluster. At the same time, there is too much moisture in the brake system, which may freeze in the cold winter, which may cause brake failure and even cause brake failure, which can be life-threatening.

Therefore, the maintenance of the brake system is particularly important. The most important thing in the maintenance of the brake system is to pay attention to the replacement of the drying tank. When the following three situations occur, the cardholder is reminded that the drying tank needs to be replaced.

1. A large amount of water can be released from the gas tank;

2. Oil droplets form at the exhaust port of the air treatment unit;

3. The use time is more than one year.

When there is a small amount of oil stain at the exhaust port of the air treatment unit, it does not need to be replaced, because this is a normal discharge phenomenon.

Pipeline air leakage is another fault phenomenon that is easy to occur in the brake system.

1. Pipeline wear, as long as we pay attention to pipeline bandaging and regular placement.

2. When installing the quick connector, it should be installed in place, and when you hear a "click" sound, it means that it is in place;

3. When installing the pipeline joint, pay attention to cleaning the oil and gray soil on the joint to prevent impurities from causing the joint to be tightly sealed, thus causing air leakage.

In the whole brake system, excessive moisture generation and pipeline air leakage are two common fault phenomena, as long as the vehicle is usually used, pay attention to replacing the drying tank and bandaging the pipeline well, so that our air brake system will not be so easy to fail.