05

2025

-

08

Truck Encyclopedia (26): The "kidney" of a truck you haven't seen before

Every time it is maintained, many cardholders will ask: What oil is better for my car? But no one has ever asked: What brand of filter should I buy?

As a component that filters oil impurities, the oil filter is cheap, but as the "kidney" of the engine, its importance is self-evident.

Today's truck encyclopedia will tell you about the structure of the oil filter.

▎If you want to change the oil for a long time, it all depends on the oil filter

When the engine is working, there will be a steady stream of metal abrasives, carbon deposits, gelatinous precipitates and other impurities mixed into the lubricating oil. In order to filter out the cleaning of the lubricating oil and extend its service life, the impurities in it must be filtered by the oil filter.

Oil filters mainly include paper spin-on filters, rotor filters, sawdust filters, etc. according to different filtration methods.

According to the different locations where they are installed, they are divided into full-flow filters and split-flow filters.

Generally, our truck engines have several filters with different capabilities: filter collector, coarse filter, fine filter and bypass filter, which are connected in parallel or in series in the engine's oil passage.

Let's start with the different types of oil filters.

● The most common and mainstream - paper spin filter

Paper spin-on filters are our most widely used oil filters. The main internal structure is composed of filter element, check valve and bypass valve. The spin-on filter is easy to replace with a single sealing point, greatly improving reliability and tightness.

Since the oil filter has to consider the oil flow and the accuracy of the overconsideration, the two are contradictory. To ensure the accuracy of excessive consideration, the flow rate must be reduced, and to ensure the flow rate, the filtering accuracy cannot be guaranteed.

Therefore, in order to find a balance between the two and ensure long oil change and engine life, the engine filter element of the truck has the disadvantages of high filtration accuracy and small flow loss by using a combination of coarse filtration and fine filtration, and also has a long filter element life.

● Can wood slag still block filter media? - Sawdust filter element

In the 70s of the last century, due to the backward production process, many oil filters in our country used sawdust filter elements as filtration equipment. Among them, the sawdust filter element also has a standard of "Jiefang Brand Sawdust Pulp Oil Filter Element Technical Conditions (Trial)" promulgated by the original Ministry of Machinery in 1975, which has been widely promoted in models such as Jiefang and Yuejin and some agricultural machinery.

Sawdust filter element, also known as wood chip filter element, is made of wood sawdust as raw material, after sorting and screening, molding, drying and dehydration. The raw materials of sawdust filter elements are widely sourced and the cost is low, but due to the dense structure of the filter element, the filtration resistance is large, and the service life is short, it can generally only be used for diversion filtration.

After later improvement, the sawdust filter element is bonded with phenolic resin as the filter element, which improves the shortcomings of high resistance and short life. However, with the great improvement of our country's production technology, it is difficult to see this type of filter element now.

● Can't stop at all – centrifugal oil filter

Centrifugal oil filter is commonly known as rotor filter. As you can guess from the name, the rotor oil filter is a device that uses centrifugal methods to separate impurities in engine oil.

The working principle of centrifugal oil filter is as follows: the oil with pressure enters the rotor filter, and the oil is sprayed out at high speed from the nozzle at the bottom of the rotor filter, forming a reaction force to push the rotor filter to rotate at high speed, and the impurities with a density greater than the oil are separated from it and settled on the rotor wall under the action of centrifugal force, and finally achieve the purpose of filtering impurities and cleaning the oil.

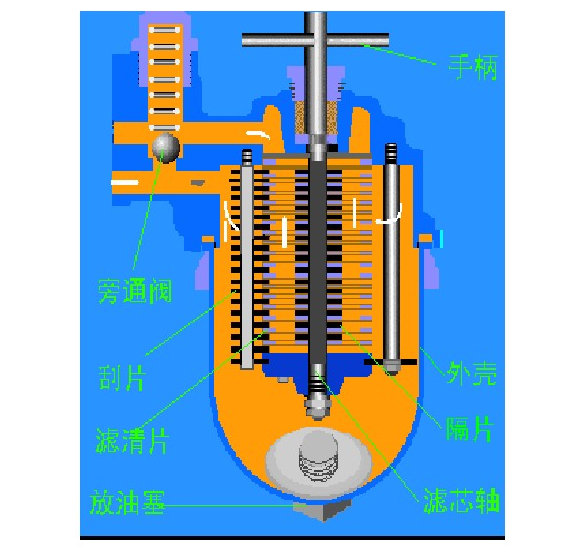

● Metal scraper filter, have you suffered it?

It can be understood as a mechanical filter with a complex structure. The principle is that several layers of steel sheets are stacked together, and when the oil passes through, it flows through the gaps, and particles and impurities are intercepted and filtered by the steel sheets. After there are more impurities, turn the handle on top, the steel sheet will rotate in the compartment, one layer does not move, and the other layer rotates, at this time the impurities will be separated.

The only advantage of the scraper oil filter is that it does not need to be replaced, and there is basically no maintenance, just get out of the car and shake it a few times. There are a lot of disadvantages, bulky and massive, complex structure, high production cost, and have basically been eliminated by the market.

▎Don't confuse oil bypass valves and oil bypass filters

● Oil bypass valve

Early oil bypass valves were a component on the engine that resembled a thermostat and had a spring to hold the valve. The difference is that thermostats rely on temperature to control the opening and closing of valves, while oil bypass valves rely on oil pressure to control opening and closing.

The purpose of designing the oil bypass valve is that when the filter paper of the filter element is blocked, the bypass valve opens under the pressure of the oil, so that the oil can pass smoothly and provide sufficient oil.

To put it bluntly, a bypass valve is a protective device. If the filter paper is blocked, the bypass valve allows the oil to flow safely and continue to maintain adequate lubrication.

● Oil bypass filter element

The principle of the oil bypass filter element is to divert a tributary in the oil circuit, which only plays the role of precision purification and filtration without participating in engine lubrication.

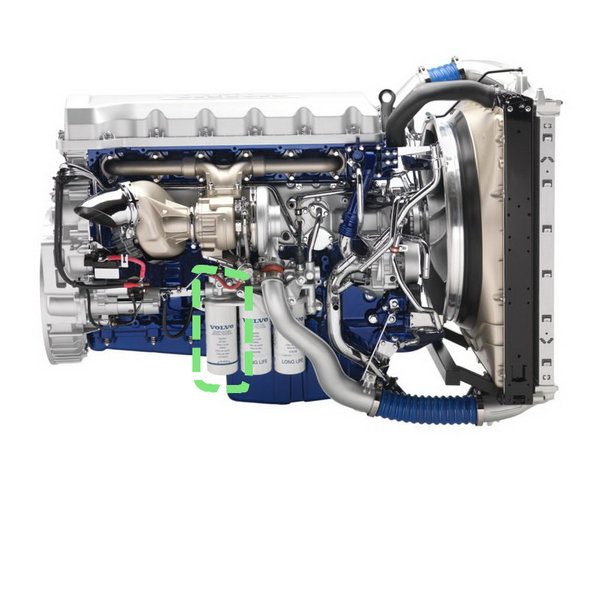

The filter element on the far left of Volvo's engine is the oil bypass filter (shown in the green circle), which is responsible for high-precision oil filtration and is an important guarantee of oil purity and life.

The oil bypass filter element only provides sufficient filtration accuracy, dispensing with large flow rates. The purpose is to ensure that the engine oil is clean and free of impurities.

To put it simply, it is a coarse and fine filter charging into battle and killing the enemy bravely. The oil bypass filter element engages in logistics in the rear and plays a role in stabilizing the morale of the army.

● Hazards of inferior filter elements

Just put 2 pictures for everyone to see.

Just imagine, once the filter paper is broken or blocked, the engine is lubricated by contaminated engine oil or lubricated without organic oil, and the cylinder is perforated at light, and the tile is overhauled.

In fact, no matter how the oil filter element works, when you buy a filter element, you must choose the oil filter element of a regular manufacturer. Otherwise, if you save a little money, you will be unlucky in the end with your own wallet.

● Editor's postscript

Well, today's truck encyclopedia article about oil filters is introduced here. I believe that after reading today's article, have you increased your knowledge again?

From sawdust filters to scraper filters to spin-on filters, every technological advancement drives improved truck performance. Provide a longer maintenance cycle for everyone, reduce the time to enter the service station as much as possible, so that everyone can have more sports cars and less maintenance.

Previous Page

Previous Page