14

2025

-

10

Tire pressure not showing? Experienced driver: The dryer should be replaced earlier.

There are two types of braking systems on vehicles: hydraulic brakes and air brakes. On trucks, air brakes are mostly used because the air brake system is characterized by quick response, high air pressure, and strong force, making it suitable for truck braking.

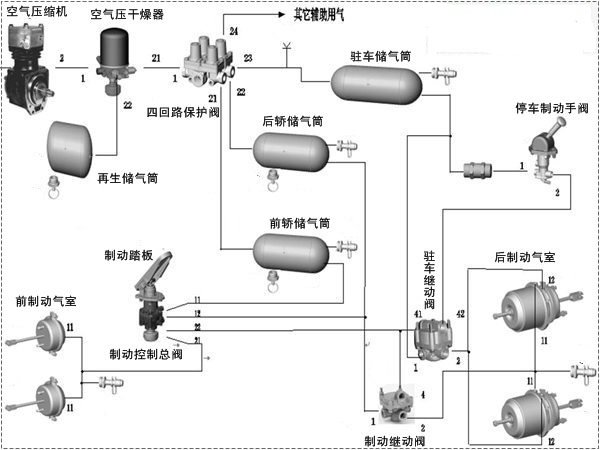

Schematic Diagram of Air Brake PrincipleThe air brake process involves air coming out of the air compressor, entering the air dryer assembly for drying treatment, passing through the air reservoir and various valves, and finally reaching the brake chamber. When the vehicle needs to brake, pressing the brake pedal initiates the braking process.

▎Two Common Failures of the Air Brake System: Excessive Moisture and Air LeakageExcessive moisture can damage components. For example, when there is too much water in the air reservoir, it can cause corrosion at the air pressure sensor connections, leading to sensor failure and resulting in the instrument panel showing no air pressure readings. Additionally, if there is too much moisture in the brake system, it can freeze during cold winter, potentially causing brake malfunctions or even brake failure, posing a life-threatening risk.

Therefore, the maintenance of the braking system is particularly important. The most important aspect of brake system maintenance is paying attention to the replacement of the dryer. When the following three situations occur, it indicates that the dryer needs to be replaced:

1. A large amount of water can be released from the air storage tank;

2. Oil droplets form at the exhaust port of the air processing unit;

3. The unit has been in use for over a year.

If there is only a small amount of oil at the exhaust port of the air processing unit, replacement is not necessary, as this is a normal discharge phenomenon.

Air leakage in the pipelines is another common fault in the brake system.

1. Pipeline wear: We just need to pay attention to proper wrapping and orderly placement of the pipelines.

2. When installing quick connectors, make sure to install them properly. When you hear a 'click' sound, it indicates that it is in place.

3. Air leakage at pipeline joints: During installation, make sure to clean off any oil and dirt on the connectors to prevent impurities from causing poor sealing, which can lead to air leakage.In the entire brake system, excessive moisture and air leakage in the pipelines are two common faults. As long as you regularly replace the dryer tank and properly wrap the pipelines during vehicle use, our pneumatic brake system will be less prone to faults.