13

2025

-

10

If you notice these issues with your brakes in winter, it's likely time for maintenance.

As winter approaches, truck drivers must ensure that the brake system is protected against water and freezing. Excess moisture in the brake system can cause serious hazards: at the least, it can lead to brake lockup that prevents the vehicle from moving or cause the wheels to catch fire and damage the vehicle; at worst, frozen brake lines can result in brake failure, increasing safety risks. Here, we share some tips to raise awareness and help avoid such situations.

▎How to Prevent Brake Line Freezing from Causing Brake Failure and Increasing Safety Hazards

First, let's talk about the problems caused by excessive moisture in the brake lines. The four circuits, brake master cylinder, trailer throttle valve, relay valve, trailer three-axle valve, or ABS control valve — as everyone knows, the entire braking system relies on these components. They work together and are indispensable; any one of them having a problem can lead to malfunction.

For example, if the brake valve does not return smoothly after releasing the brake, it can cause a phenomenon known as dragging brakes, which can range from mild to severe, with some wheels locking and others not, especially when the brakes drag without locking.

Due to the heavy inertia when carrying loads, drivers may not notice this, and it is at this time that the temperature of brake drums can spike, potentially causing tires to catch fire and resulting in property damage. The cause is either water in the brake valve or the addition of air line antifreeze, both of which are hazardous.

Here are a few key points: accumulated water can damage the grease inside the brake valve, making the control piston seals dry and stiff. During braking, the piston and the valve body wall undergo dry friction, losing normal sliding coordination. After releasing the brake, this affects the piston's return. In an emergency braking situation, the piston may get stuck; if the piston cannot move down, the valve cannot open, causing brake failure, which can have catastrophic consequences.

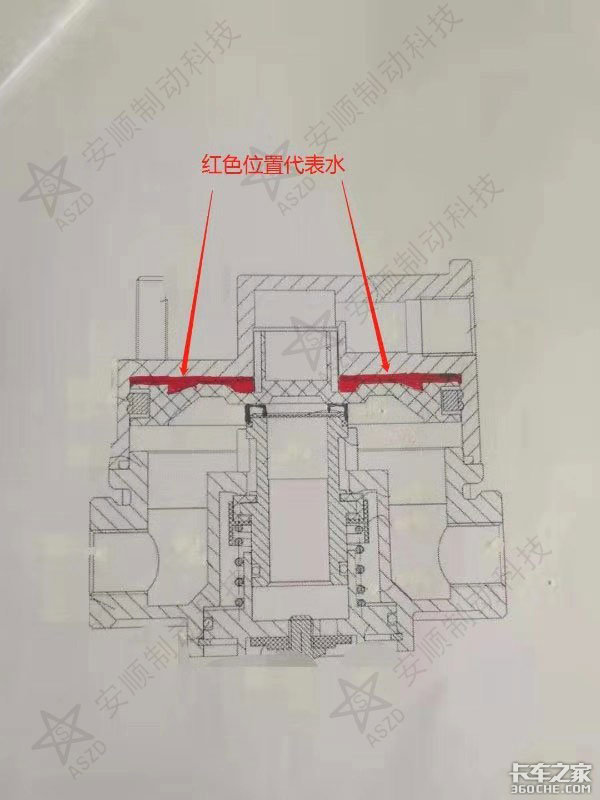

If there is excessive moisture accumulating above the piston, the piston is pressed by the water above and cannot return to its original position, causing it to fail to completely separate from the valve below. A small amount of air may still enter the brake cylinder, causing continued braking. Figure 1

图1

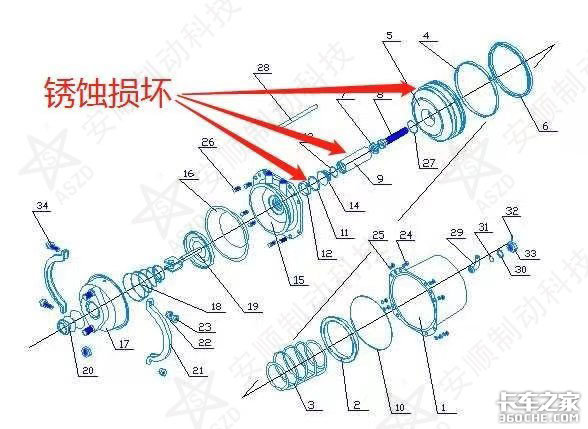

The reason for brake issues is as mentioned above. Some vehicles incur damage due to the problems described, and certain truck drivers may blame the repair personnel or a specific pump valve. In reality, the main culprit is the moisture in the braking system and the failure of the drivers themselves to inspect and maintain the braking system. What caused the brake valve to be in its current state in the picture below?

▎ What caused the brake valve damage?

图2

图3

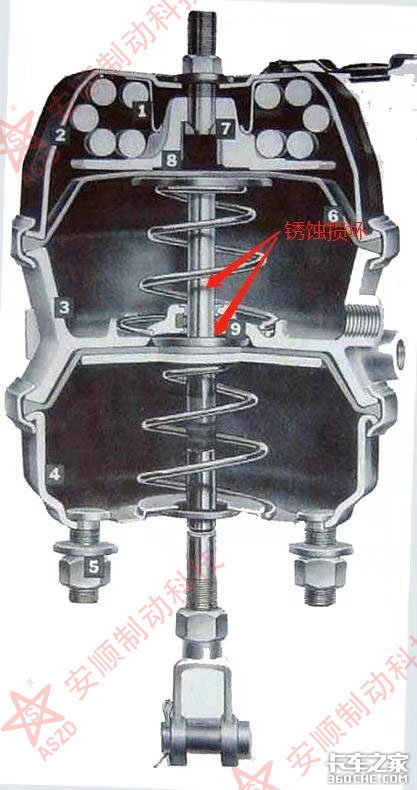

As car enthusiasts probably know, moisture in the brake lines or antifreeze in the air circuit not only damages the brake valve piston chamber, but also damages the return spring of the valve in the brake valve air chamber, causing it to rust or break, which results in air leakage from the brake valve. At the same time, it can also damage the brake wheel cylinder (brake air chamber); let's first talk about the wheel cylinders of the main vehicle.

图4。

图4

Damaging the middle partition O-ring or a corroded push rod can cause air leakage. When the handbrake is released, air pressure can pass from the service brake chamber to the foot brake chamber. Rust on the service brake piston and the inner wall of the service brake cylinder causes dry friction, leading to sticking, which reduces or even results in the loss of service brake function. The same situation occurs with trailer brake chambers.

图5。

图5

The push rod between the corroded front brake chamber and the foot brake chamber can damage the O-ring, also causing air leaks. Truck drivers can summarize that if you have the above issues, not only will the repair costs of the braking system increase significantly, but most importantly, safety is compromised. There are many hazards caused by moisture in the brake system that are too numerous to list.

Imagine what could happen if there is water in the brake lines and it freezes in winter. Some drivers might initially think that the handbrake won't release and the vehicle can't move.

Congratulations, you got half of it right: a stuck handbrake can prevent the vehicle from moving, but this is not the most dangerous scenario. The worst case is if the air supply or control lines of the foot brake valve freeze. Then, even if you want to stop, you can't, and that is truly terrifying. In other words, if the brake lines fail to transmit air while driving, the consequences are obvious to any experienced driver.

After more than 20 years working with brake systems, I have seen this happen countless times. Drivers must take preventive measures and control moisture at the source. Many think that simply replacing the air dryer is enough, but not all dryers are effective; the quality of molecular sieve particles inside varies widely.

Many inferior models have no actual drying capability and are just decorative. Some drivers replace the original dryer, which contained no water, with a new dryer, only to find that the new one releases a lot of water—clearly illustrating the problem.

At this point, it’s important to note that the effectiveness of the dryer in controlling moisture is not determined by quality alone. Factors such as the air compressor, condenser configuration, piping layout, temperature, and backflush setup all affect performance. By upgrading these technical installations, moisture can be effectively controlled.