29

2025

-

09

Brakes without using air? Get to know the electronic mechanical braking system.

If in the future braking were to abandon our traditional air pump, what do you think would happen? Let's talk about it today.

Air brakes are almost considered common knowledge for heavy trucks. We also checked forums and found that many truck drivers discuss issues related to air brakes, such as air pump wear and air leaks in the lines.

To help truck drivers better understand, let's first talk about the basic principles of air brakes before moving on to today's topic.

Baidu Encyclopedia states: 'Braking, also known as deceleration, refers to the action of stopping or reducing the speed of locomotives, vehicles, and other transportation tools or machinery in motion.'

In simple terms, it is the action of making a vehicle stop. When applied to a braking system, it is actually a form of energy conversion.

Simply put, in the braking system, through the friction between the brake pads and the brake disc (or between the brake shoes and the brake drum), the kinetic energy accumulated from the vehicle's motion is converted into heat energy generated by friction, which is then dissipated into the air.

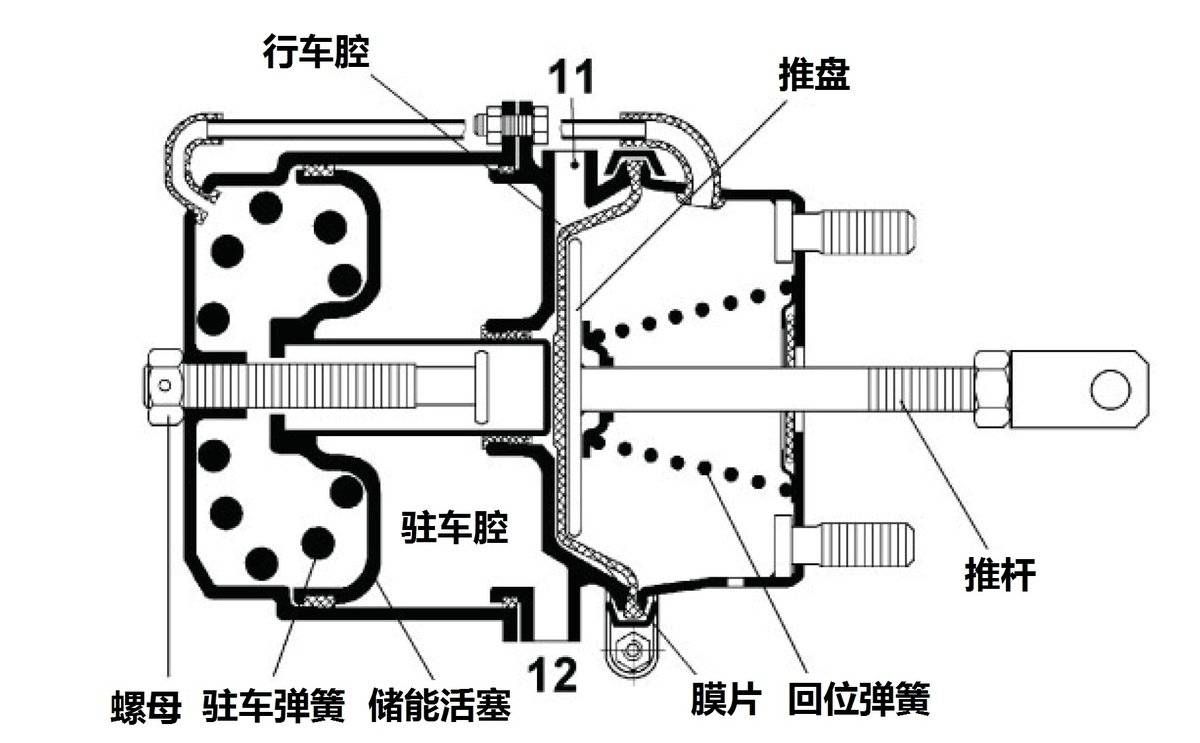

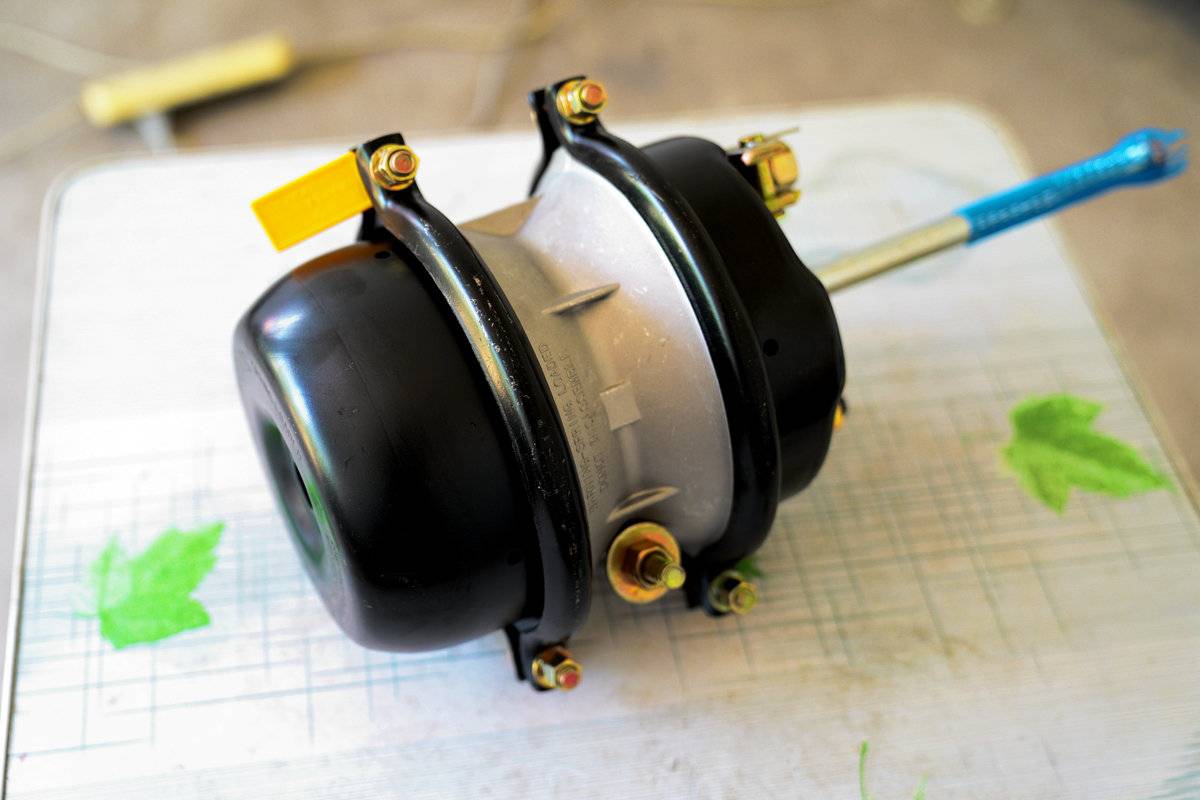

The air brakes on our truck are mainly composed of an air pump, an air storage tank, and the brake chambers (brake actuators). When we press the brake, the compressed air accumulated in the air tank by the air pump is released into the brake chambers, which then pushes the diaphragm to generate force, subsequently actuating the brake calipers or brake drums to achieve braking.

In this system, if any component such as the air pump, air tank, valve, pipeline, brake slave cylinder, or even the diaphragm or spring inside the slave cylinder malfunctions, the braking system can show abnormalities or even fail. Therefore, many people discuss air brake faults or other issues on forums.

In addition, we will find that there are many steps of energy conversion inside. For example, the power output by the engine must be transformed into high-pressure gas through an air pump. Then the pressure of the air must be converted back into kinetic energy in the brake booster to drive the brakes. A large amount of transmission and conversion can very likely lead to energy loss. For our vehicle, this means that a lot of fuel may be wasted unnecessarily.

If the brakes are used without air, what should be used? How do truck drivers feel about using electric brakes? This is precisely what we are going to talk about today—electronic brakes.

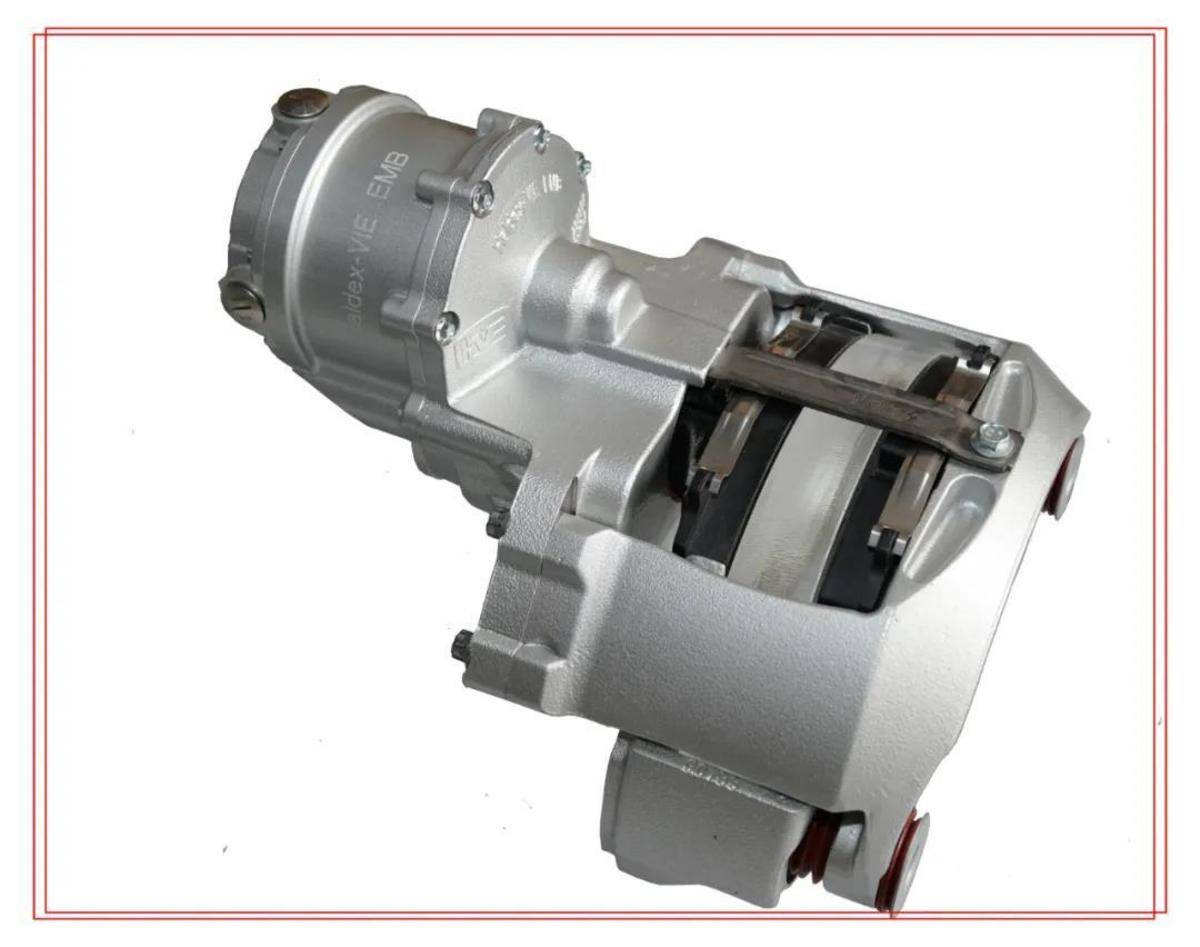

In fact, what is called an electronic brake should be fully referred to as an 'Electromechanical Brake (EMB),' which is commonly abbreviated as 'EMB.'Compared to traditional air brakes, the difference is not that significant. The biggest change is that the original air-driven system has been replaced by a motor-driven system.

We found a paper titled "Analysis of the Principles and Control Methods of Electronic Mechanical Brakes (EMB)" on the 'Fresh Graduate Network,' which discussed information about the structure of EMB. According to the paper: 'In the widely used modern electronic mechanical brakes, they mainly consist of an EMB controller, EMB motor controller, reduction device, motor, motion conversion device, electronic brake pedal, and communication network.'

We can understand it this way: when we press the brake, the EMB controller sends a signal to the motor, causing it to start working and clamp the brake through its own rotation, bringing the vehicle to a stop. When we release the brake, the motor will reverse or release the brake, allowing the vehicle to continue driving. So what are the benefits of doing this? On one hand, it simplifies the brake structure, turning the original components like air pump, air tank, valve body, and wheel cylinders into just a motor, controller, and battery.

The structure has been simplified, which reduces the number of components, thereby lowering the failure rate of the braking system. After all, everyone knows that the more intricate something is, the more likely it is to break down. In addition, there is another key benefit: fuel savings. Why does it save fuel? Let's take a look at a set of data.

Earlier, we mentioned that the air brake undergoes multiple energy conversions. For example, the air pump, also known as an air compressor, if it is electric, has an efficiency of only about 24%. After the compressed air passes through the dryer, its efficiency further drops to around 85%.

In addition, air reservoirs, brake chambers, and so on also cause efficiency losses. Data shows that, in the end, the overall efficiency can only reach about 15%.

The EMB electric brake uses the generator found in traditional vehicles, and it is not even needed in hybrid or electric cars. It draws energy directly from the battery to power the motor, then performs actions through the gear set and caliper, ultimately achieving an efficiency of around 41%.

And the energy saved in this way, when applied to vehicles, translates into reduced fuel and electricity consumption. In other words, this can make gasoline cars more fuel-efficient and electric cars run longer. ● Editor's Note:In fact, besides these benefits, electronic braking systems can respond faster because the electrical signals are transmitted more quickly, eliminating the time needed for pneumatic brakes to build air pressure. This also provides a better user experience. So, what is your opinion on this technology?

Previous Page

Previous Page