02

2025

-

09

How does a truck's "shut-off brake" work? How do you release the brakes if there is no air pressure?

The parking brake system of trucks and buses is commonly known as the "gas brake", and after parking, the driver only needs to pull a valve on the dashboard, and a "booming" sound is heard from under the car, and then the car stops steadily in place. The car also has to "boom the air pressure" before driving, and the car can start only after the air pressure exceeds a certain pressure. So how does this set of air-breaking brakes work? Today we will talk in detail about the structure and working principle of truck air brakes, and how to make the car drive without air pressure.

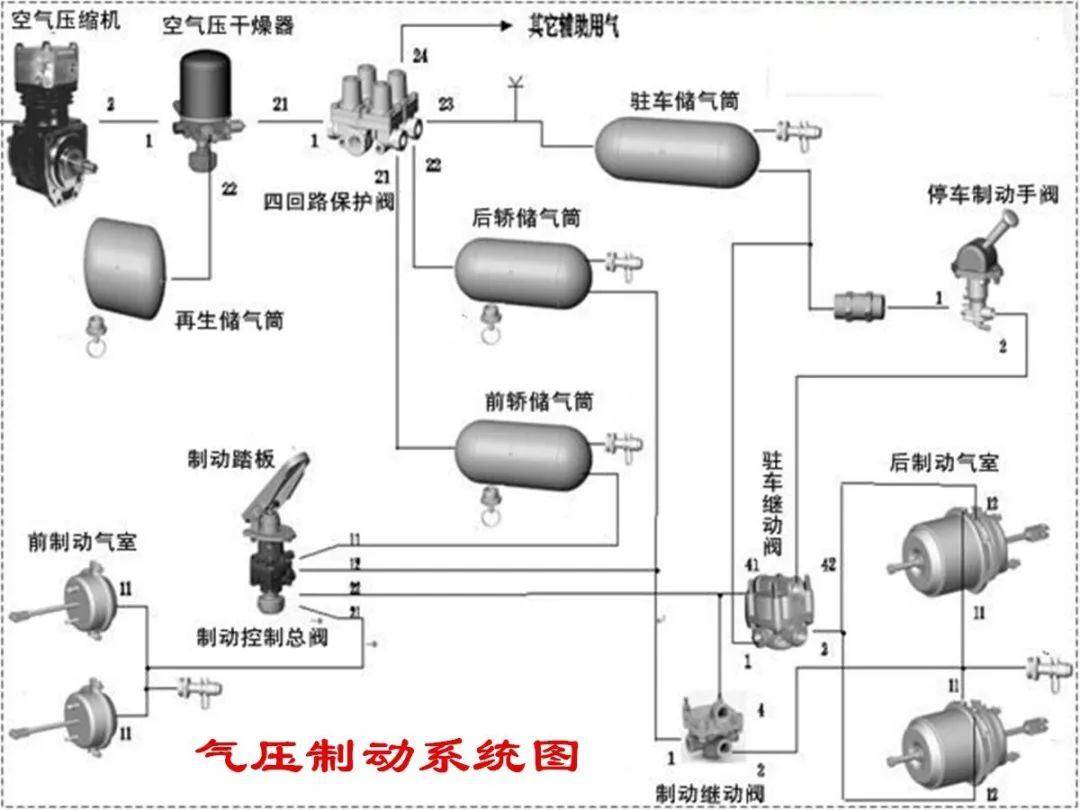

First, let's take a look at the working principle diagram of a common air brake system. The pneumatic brake system is a power brake system that uses compressed air as a power source, which is often used in trucks and large trucks, and the braking force is greater than that of hydraulic brake systems, but the system structure is complex and has many components. When the car needs to brake, the driver controls the brake pedal, opens the control valve of the brake master cylinder, and allows the compressed air in the gas reservoir to enter the brake cylinder, push the brake pump to open outward, and then push the wheel brake to action, generating braking force to slow down the car until it stops. When one set of pipelines loses the braking effect, the other set of pipelines can still continue to work normally to avoid the complete loss of braking power of the car.

In order to make the car safer and more reliable, there are generally four sets of braking devices on the car, namely the driving brake system, the parking brake system, the emergency braking system and the auxiliary braking system. The driving brake system and the parking brake system share a set of wheel brakes, but their control systems are completely separate, and when one system fails, the other system can also make the car stop reliably; The emergency braking system is generally the same set of devices as the parking brake system, but some devices are attached to it; Auxiliary braking systems include exhaust brakes, hydraulic retarders, eddy current retarders, etc., which can enhance the braking force to a certain extent and reduce the load on the braking system, but cannot make the car stop completely.

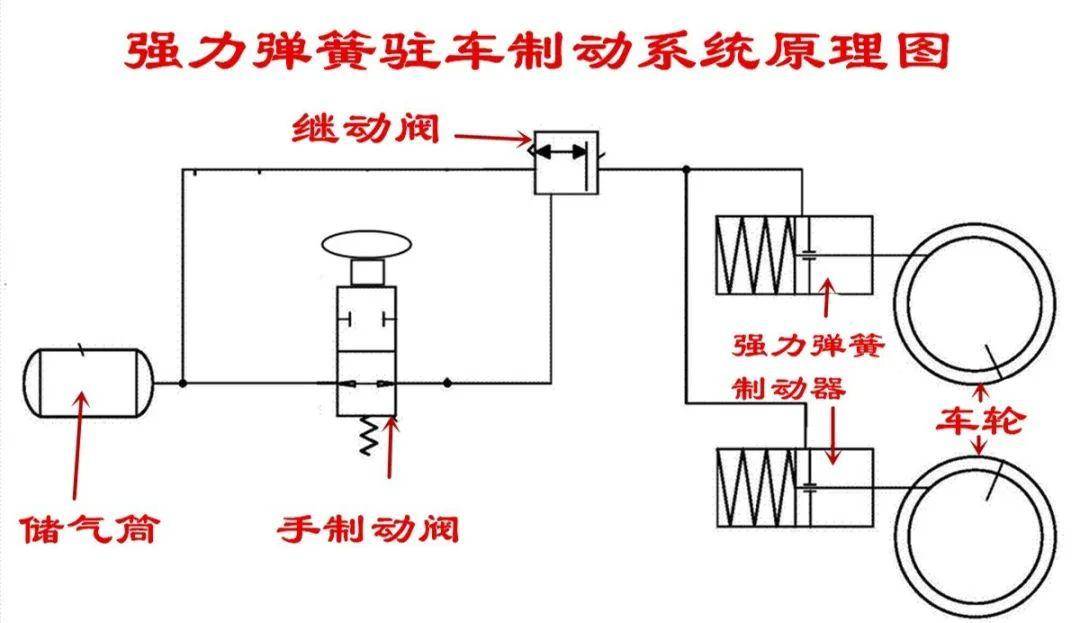

Nowadays, large trucks and large buses that use pneumatic brake types usually use strong spring parking brakes in their parking brake systems, which are commonly known as "air brakes". The following picture is a common power spring parking brake system working principle diagram, we use this diagram to analyze its working principle. There are three main components in this system, namely hand brake valve, relay valve, and strong spring parking brake, let's first take a look at the structure and working principle of these components.

1. Hand brake valve

The hand brake valve is essentially a switch valve, and its interior is actually a two-position tee stem. When the car is driving normally, the hand brake valve is in the open state, and the compressed air in the gas reservoir leads to the relay valve, so that the relay valve is opened, and the compressed air enters the strong spring brake, so that the strong spring is compressed, and the parking brake is released; When the car stops, the hand brake valve is disconnected, cutting off the pipeline between the gas reservoir and the relay valve, the relay valve is closed, the compressed air is discharged, and the strong spring parking brake spring is ejected, so that the wheel brake brakes are braked, so that the car can stop reliably.

The hand brake valve is also an emergency brake valve on the car. When the car's service brake system fails, the operator hand brake valve can not only stop the car, but also control the amount of the car's braking force at any time. The hand brake valve has a follow-up action, different handle angles, and different relay valve openings, so as to control the amount of wheel braking force. When it is fully closed, maximum parking braking force is generated. Generally speaking, the maximum parking braking force of a car is greater than 60% of the maximum driving braking force. Therefore, the parking brake of the truck is very powerful, and it is generally required to be reliably parked on a 30% slope when fully loaded.

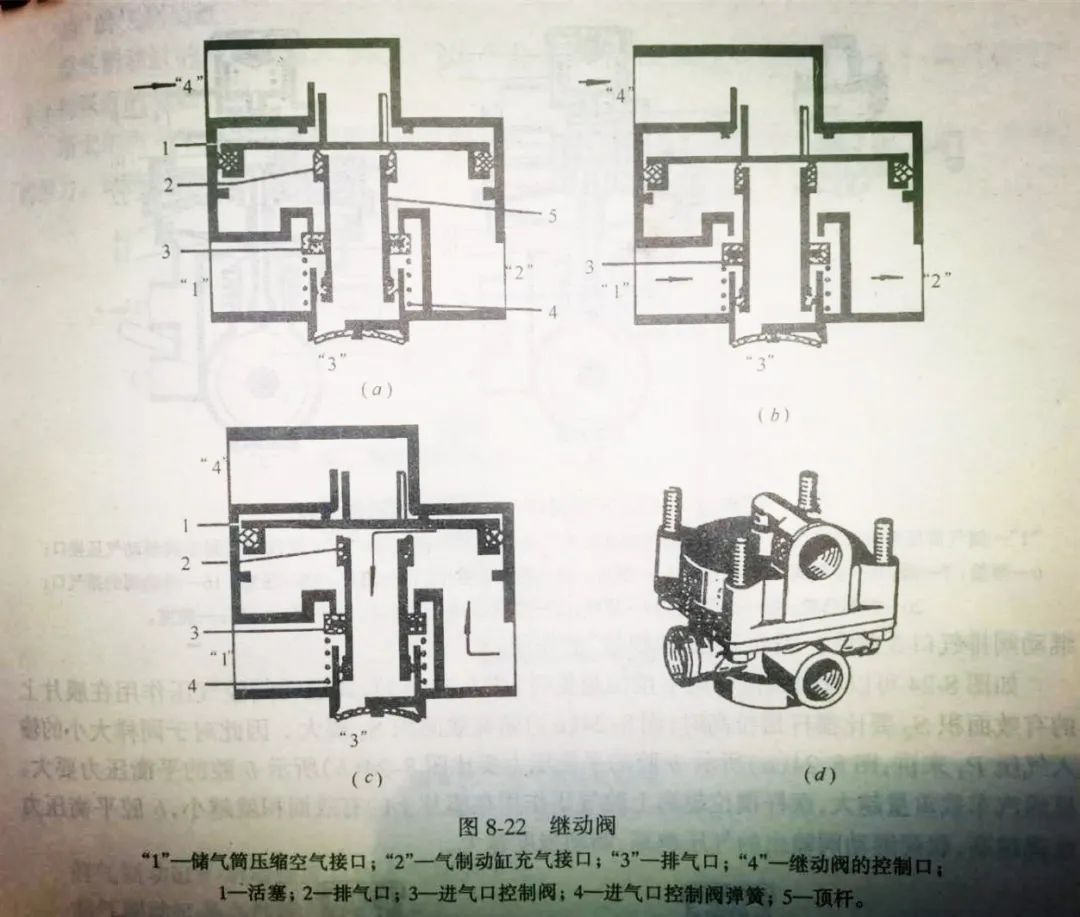

2. A relay valve

The essence of the relay valve is an amplification valve, which only plays a role in controlling the air volume with a small air volume, but does not change the braking performance of the car. In addition, due to the relatively long wheelbase of the truck, the distance between the brake master cylinder and the brake cylinder is long, and the air capacity of the rear axle brake cylinder is relatively large. For this reason, a relay valve is set up closest to the rear brake sub-pump, which is directly supplied by the gas reservoir through a thicker gas pipe, and a thinner gas pipe on the brake master pump controls the opening and closing of the relay valve, which can greatly shorten the braking response time and play a role of "fast charging and quick release". Its working principle is shown in the figure below, the number "1" on the interface indicates the air intake, "2" indicates the air outlet, "3" means the exhaust port, and "4" indicates the control air port.

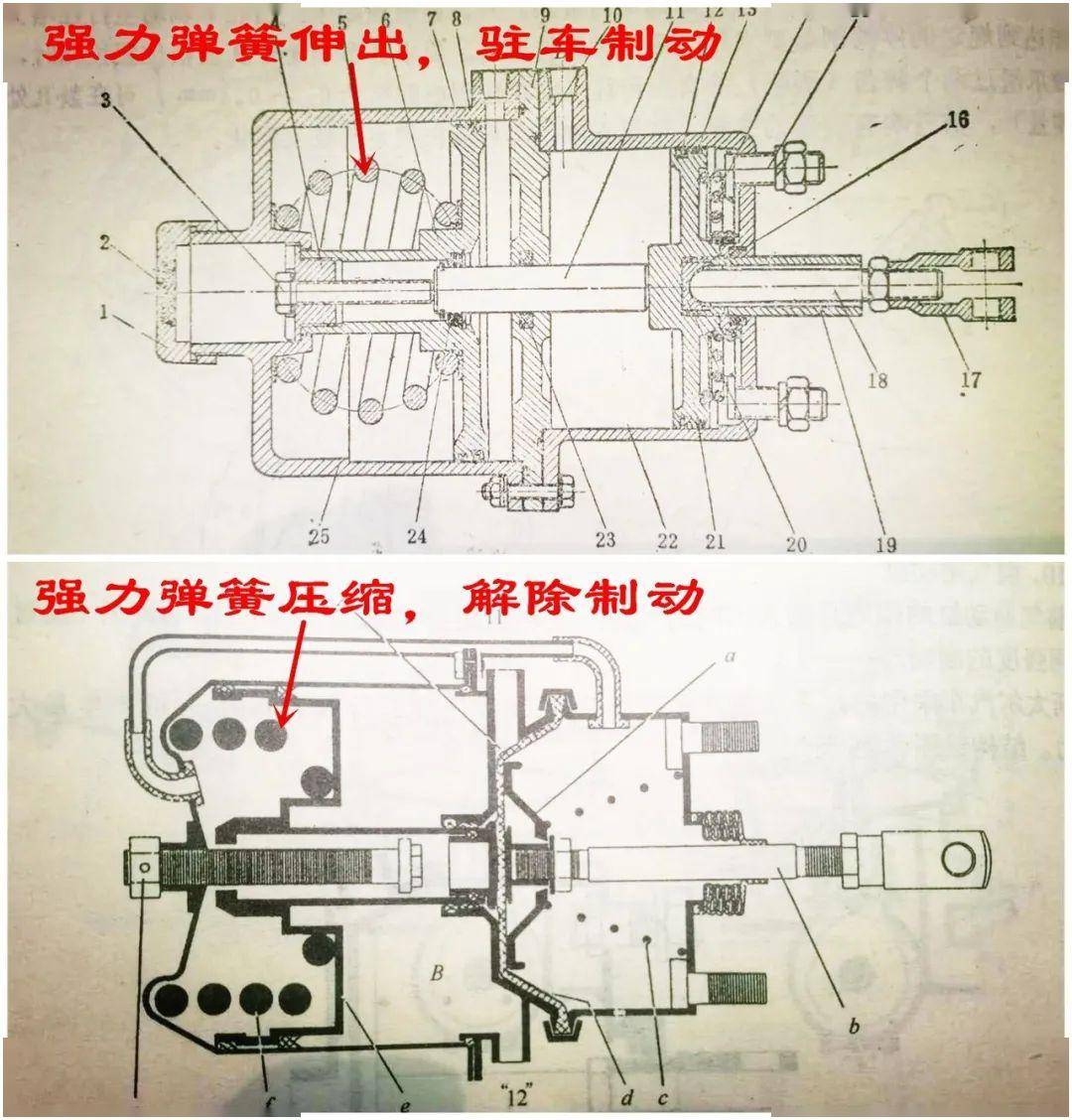

3. Strong spring parking brake

The power spring parking brake is the most core and technically complex component of the system, and if the hand brake valve and relay valve are the control elements, then it is the actuator. It is a complex with both the dual functions of driving brake and parking brake, the driving brake air chamber and the parking brake air chamber are separated by partitions, respectively controlled by the driving brake control pipeline and the parking brake control pipeline, the two operate independently, but share a set of actuators.

The specific structure and working principle of the power spring parking brake are as follows. It is generally divided into two parts, the front is the driving brake chamber, the brake piston retracts under the action of the spring in the normal driving state, and does not generate braking force; When the brake pedal is depressed, compressed air enters the rear of the front air chamber running brake piston, pushing the pusher outward, which in turn pushes the wheel brake action and generates braking force. The second half is the parking brake, which has a strong spring inside (the elastic force is about 5000N), when the car stops, the strong spring sticks out, pushing the driving brake piston outward, pushing the wheel brake action to generate braking force, which is about 60% of the maximum braking force of the car; When the car is running normally and the air pressure is sufficient, the hand brake valve opens, and the compressed air enters the parking brake air chamber in front of the power spring through the relay valve, compressing the strong spring to the limit position, so as to release the parking brake.

The working process of the whole system is as follows: starting the car, When the air pressure of the brake system reaches more than 0.65MPa, release the hand brake valve, and the compressed air enters the upper part of the relay valve piston, so that the piston goes down, and open the relay valve; Wait for the compressed air at the air inlet of the relay valve to instantly pass through the relay valve, enter the parking brake chamber of the powerful spring parking brake from the air outlet, compress the strong spring to the limit position, so that the parking brake is released; When stopping, the driver pulls the hand brake valve, and the compressed air above the piston in the relay valve is discharged from the hand brake valve, and then the relay valve is closed under the action of the spring, and the exhaust port is opened, and the compressed air in the parking brake chamber is discharged from the exhaust port of the relay valve, and the strong spring is ejected , pushing the wheel brake brake.

If the driving brake system fails while driving, the parking brake system acts as an emergency braking system. The driver pulls the hand brake valve handle to control the pressure entering the relay valve piston, and then controls the opening of the relay valve, so that the pressure of the compressed air entering the parking brake chamber is not enough to fully compress the strong spring, and the strong spring at this time is partially extended, pushing the wheel brake to generate part of the braking force and slow down the car. When the hand brake valve is fully closed, the power spring is fully extended and the emergency braking force is maximized. In addition, if the braking system of the car is insufficient or has no pressure at all due to pipeline leakage and other reasons, the parking brake power spring is fully pushed out, so that the car can be reliably stopped in place, so this "air break brake" is also known as the safest braking system.

Then if there is a car engine failure, or for some reason there is no pressure in the braking system, at this time the power spring is always in the extended position, and the wheels maintain maximum braking force. If you need to start or tow the car at this time, how to release the parking brake? In this case, we just need to screw out one of the screws behind the parking brake chamber. The front end of this screw is connected to the parking brake piston, and when it rotates outward, it can compress the power spring, thereby releasing the force of the force spring on the wheel brake, and the brake is thus released. It should be noted that before unscrewing this screw, the wheels must be covered to prevent injuries caused by the movement of the car at the moment when the parking brake is released.

The most common failure of the power spring parking brake system is air leakage. It should be noted that many times the air leakage part is not necessarily the fault part, we need to analyze what part is faulty according to the working principle of this system. For example, the exhaust port of the hand brake valve leaks, many times it is not the hand brake valve that is broken, but the internal seal of the relay valve is damaged, and the air leakage flows into the hand brake valve and discharges from the exhaust port. In addition, when the hand brake valve is released, air leaks from the exhaust port of the brake master cylinder, and the hand brake valve is pulled up. We can use a screwdriver to put it on the brake sub-cylinder when the hand brake valve is released, and if we hear the sound of airflow inside the brake sub-pump, it means that the brake sub-pump is leaking, just replace it.

In addition, in the winter in the north, if the gas tank is not discharged in time, the brake system will have too much moisture, which will also cause the brake system pipeline to freeze, resulting in failures such as the parking brake cannot be released. This kind of failure is very troublesome, because there are many fault points, every pipeline joint has the possibility of freezing, and we cannot open all the pipelines for inspection, so in this case, it is generally to drive the car to the warm storage to thaw and wait for the ice to melt. If there is no warm storage, you can only hit the luck, dismantling the pipeline joints section by section until the frozen part is found. Therefore, before the car enters winter, be sure to replace the drying tank, put the water in the gas tank clean, and insist on releasing water every day during use to prevent the brake line from freezing.