06

2025

-

05

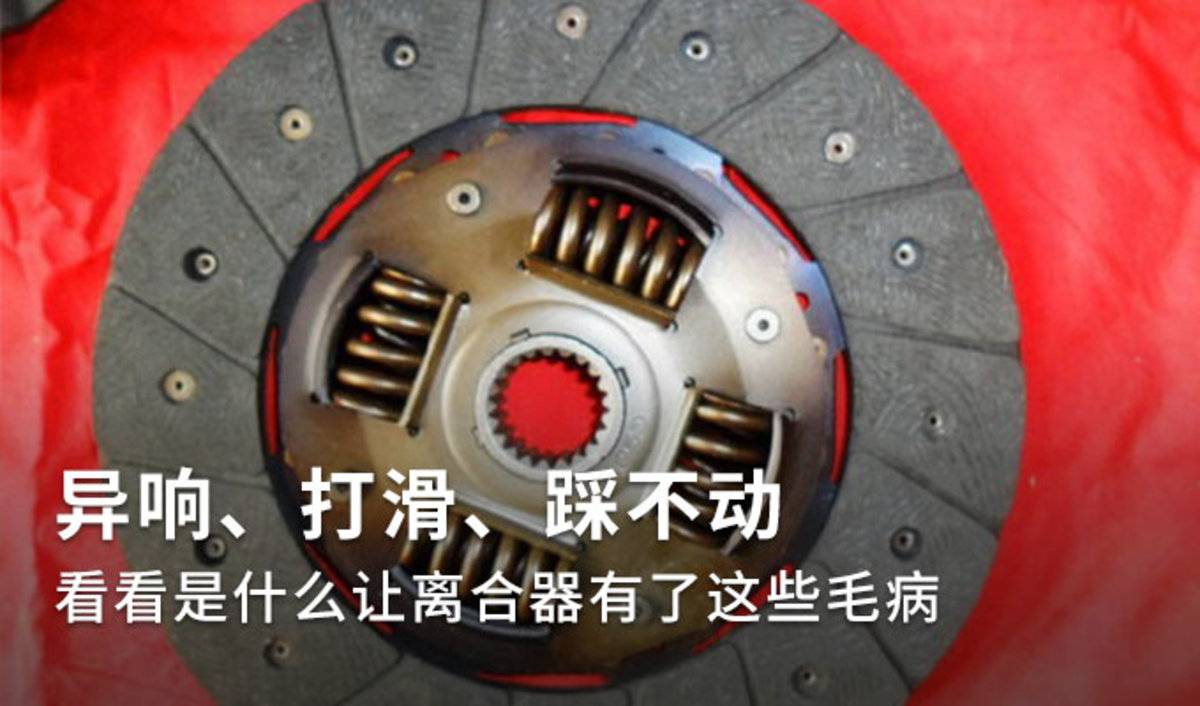

Abnormal noises, slipping, and unresponsive clutch: A brief analysis of clutch faults.

In recent years, the development trend of automatic transmissions has been very rapid, but in the current commercial vehicle market, manual transmissions are still the choice for most models. To operate vehicles with manual gearboxes, the use of a clutch is inevitable, so issues related to the clutch are unavoidable for most truck drivers.

Today we saw a light truck card friend in the community posted a related help post, let's take a look at the most common problems encountered in the clutch.

● The role of the clutch

As an indispensable part of the truck's driving process, the transmission system is mainly responsible for transmitting the power of the engine to the drive wheels, and the clutch installed between the engine flywheel and the transmission is responsible for transmitting and cutting off the power. Power can be transmitted smoothly during the start of the car and quickly cut off during transmission shifts or braking.

So why add such a "switch" to the drivetrain? Wouldn't it be more convenient to connect the engine flywheel directly to the gearbox?

Of course not, you can think about it, today's engines can increase their speed from a standstill state to a few thousand revolutions per second in a second or two, and the change is very rapid. However, the body mass of the vehicle is much heavier than the engine, and it is difficult to change greatly in a short period of time to absorb such a large amount of kinetic energy.

Although there is also a gearbox, it cannot turn on or off the power transmission between the two, and if the gearbox is directly undertaken, it will easily cause damage to its internal gears. Therefore, in manual transmission models, the clutch becomes an indispensable part of the power transmission process.

● Clutch workflow

At present, automotive clutches can be divided into hydraulic couplings, electromagnetic clutches, friction clutches, etc. Trucks such as light trucks generally use friction clutches, and as its name suggests, this type of clutch mainly transmits power through frictional resistance. Generally, it is composed of five parts: the active part, the driven disc, the pressing device, the separating device and the control mechanism.

Let's take a brief look at the workflow of friction clutches:

"The engine flywheel, clutch cover and pressure plate are the active parts of the clutch, and the driven disc with friction plates is connected to the output shaft = by splines. The compression spring pushes the pressure plate towards the flywheel, and the follower plate is pressed against the rear end of the flywheel by the pressure plate, and the engine power is transmitted to the transmission through the friction of the two surfaces.

The function of the control mechanism is to transmit the operating force of the clutch pedal, so that the pressure plate overcomes the elastic force of the spring and stays away from the wheel under the action of the separation lever, and the driven plate is disengaged from the pressure plate and the flywheel and interrupts the power transmission. Quoted from Baidu Encyclopedia

● Frequently Asked Questions:

We all know that manual transmission models will often shift gears during use, which is inseparable from the clutch, in frequent use, some parts of the clutch may be worn, deformed or ruptured due to the effect of friction, so that the friction torque is reduced, and lead to clutch system failure.

In order to prolong the service life of the clutch, it is important to maintain the clutch system properly and effectively. Today, let's take a look at some of the most common problems encountered by cardholders in their daily driving process.

1. Clutch slippage

Fault phenomenon: the clutch will slip when pressed, even if the clutch pedal is completely relaxed when starting, the car is still difficult to start or cannot start; Or when the car is moving, the speed of the car cannot be increased with the increase of engine speed, and it will feel powerless.

Cause of failure and solution: Clutch slippage is the relative slippage of the main and driven parts in the process of force transmission in the clutch engagement state. The root cause is a decrease in the friction factor of the friction element or a decrease in the compression force of the hold-down mechanism, which reduces its ability to transmit torque.

For example, the clutch slips can be caused by oil contamination, burn deterioration, thinning, compression spring failure, and insufficient free travel of the pedal.

This requires the card holder to check whether the free stroke of the clutch pedal is too small, if the free stroke is too small, adjust it, and then remove the clutch to check whether the friction plate is too thin, oily, hardened or exposed rivets.

2. The clutch pedal is heavy and cannot be stepped on

Fault phenomenon: The foot pedal clutch pedal is heavy, and it has to be very hard every time you press it.

Causes and solutions to failures: This is mainly due to the following reasons: improper adjustment of the separation master pump assembly, too high pedal, and no idle stroke; If the friction plate is too abrasive, the friction provided by the same force will be smaller, in addition to excessive wear on the flywheel face, pressure plate face and release bearing.

First of all, check whether the clutch pedal is too high, whether the idle stroke is appropriate, and adjust to the normal state. Then check the wear of the clutch disc assembly, cover assembly, and flywheel, and replace it in time if it exceeds normal wear.

3. Clutch abnormal noise

Fault phenomenon: Just step on the clutch pedal a little, you will hear a "click, click, click" sound, and it will be accompanied by a sound when starting to engage or when disengaging in the middle of the march.

Cause of failure and solution: This is mostly the separation bearing lack of oil or damage, need to be filled with lubricating oil, if there is no effect, you need to replace a new one, you can also check whether the driven disc or pressure plate is broken, if it is broken, it needs to be replaced in time.

4. The clutch is not completely separated

Fault phenomenon: the engine is idling, the clutch pedal is pressed, there is a gear impact sound when the gear is in gear, and it is difficult to gear in gear.

Cause of failure and solution: the free stroke of the clutch pedal is too large; Warping and deformation of the follower or rupture of the friction plate; Oil leaks from the hydraulic system or there is air inside the system.

First of all, check and adjust the free stroke of the clutch pedal, if it is too large, it needs to be adjusted even if it is too large, and check whether there is oil leakage and air intake in the clutch hydraulic system. If it occurs, it is necessary to tighten the joints in time to replace the seals of the master cylinder and the working cylinder, and exhaust the air inside the system.

● Afterword:

A large part of the above problems are caused by bad driving habits, for example, many cardholders are used to putting their feet on the pedal all the time when driving, so that the operation will make the clutch pressure plate and the moving disc in a state of slipping while turning, and let the clutch disc friction plate overheat, causing damage or even burning.

Therefore, in daily use, we still have to develop good driving habits, and usually check more and pay more attention to the condition of the clutch. So if there is anything else you want to know, please leave a message in the comment area.